TRANSMISSION SHIFT MODE SELECTOR SWITCH

The transmission shift mode selector switch is used to switch

the transmission between the automatic shift and manual, and

also change the shift point when the auto-shift mode is select-

ed.

When this switch is at (B) or (C) position, the transmission is

set in the auto-shift mode and the automatic shift pilot lamp

lights up on the machine monitor. Normally, set it to auto-shift

mode.

Position (A): The manual shift mode is set and the machine

travels at the gear speed displayed on the shift indicator.

Position (B):Travel speed when shifted up is low (level ground,

normal travel)

Position (C):Travel speed when shifted up is high (uphill, full throttle travel)

When most of the machine operations is done on a level ground, selecting position (B) allows shifting up the

gear at a low engine speed, and it enables to reduce the fuel consumption.

REMARK

For details of the manual shift, see “MANUAL SHIFT (3-105)”.

For detail of the automatic shift, see “AUTOMATIC SHIFT (3-105)”.

However, when E light mode or E mode is selected to reduce the fuel consumption, the shift point remains un-

changed whichever you may choose, (B) or (C).

Lamp for the transmission shift mode selector switch lights up when position of (A) or (C) is selected.

Lamp does not light up when position (B) is selected.

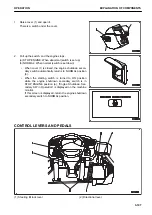

TORQUE CONVERTER LOCKUP SWITCH

The torque converter lockup switch is used to turn the torque converter lockup function ON and OFF.

Each time position (A) of the switch is pressed, the function switches between ON and OFF.

If you release your hand from the switch, it automatically returns to its original position.

For setting when the starting key is in ON position, see “LOCK-

UP FUNCTION SETTING WHEN KEY IS ON (3-72)”.

ON

The lockup operates according to the travel speed and working

condition.

OFF

The lockup function is disabled.

For detail, see “HANDLE TORQUE CONVERTER LOCKUP

(3-200)”.

REMARK

Usually, select ON mode to work with less fuel consumption.

DIRECTIONAL SELECTOR ENABLE SWITCH ON R.H. SWITCH PANEL

(if equipped)

EXPLANATION OF COMPONENTS

OPERATION

3-102

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...