FOREWORD

MAINTENANCE STANDARD TERMINOLOGY

00-8

WA470-6, WA480-6

12

MAINTENANCE STANDARD TERMINOLOGY

00

The maintenance standard chapter explains the criteria for replacing or reusing products and parts in the machine maintenance

work. The following terms are used to explain the criteria.

1.

Standard size and tolerance

•

To be accurate, the finishing size of parts is a little different from one to another.

•

To specify a finishing size of a part, a temporary standard size is set and an allowable difference from that size is indi-

cated.

•

The above size set temporarily is called the “standard size” and the range of difference from the standard size is called

the “tolerance”.

•

The tolerance with the symbols of + or – is indicated on the right side of the standard size.

•

•

The tolerance may be indicated in the text and a table as [stan-

dard size (upper limit of tolerance/lower limit of tolerance)].

Example) 120 (–0.022/–0.126)

•

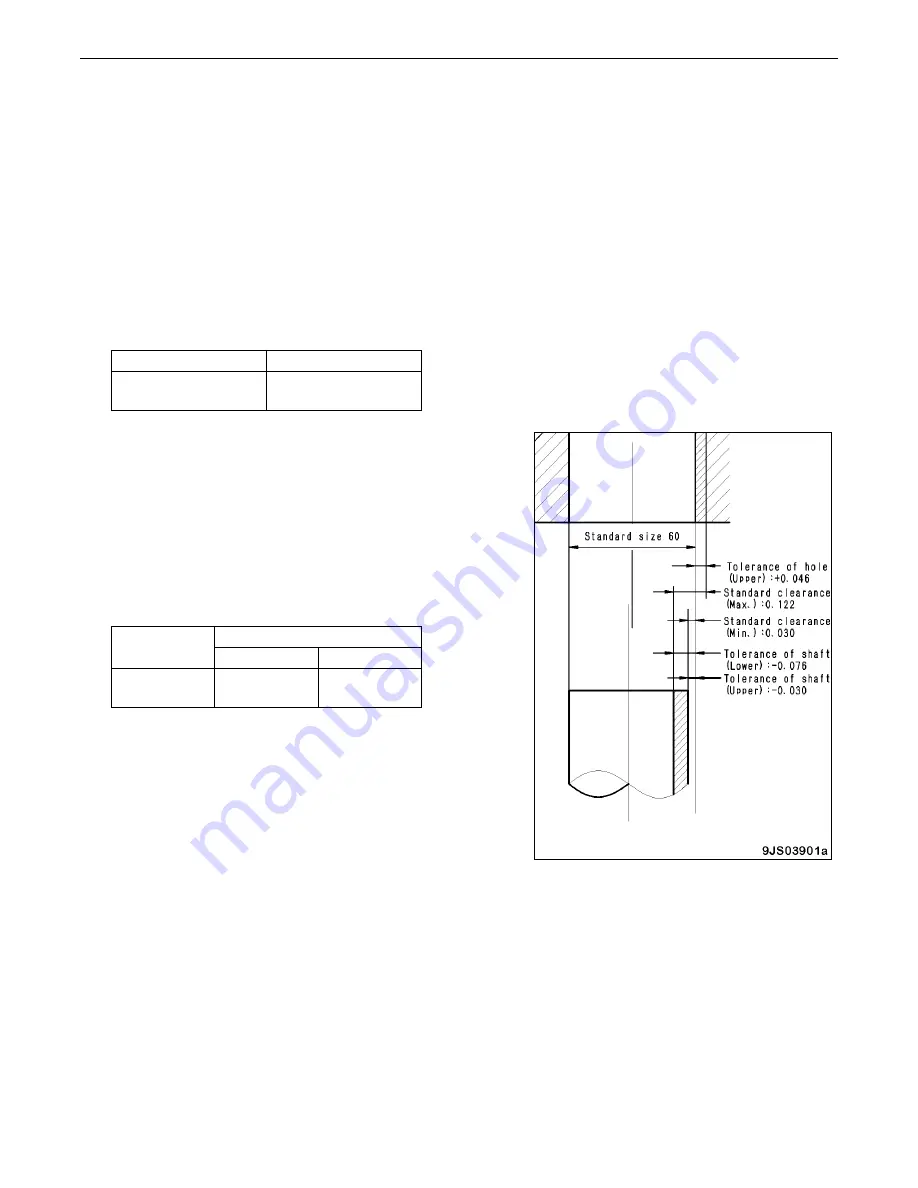

Usually, the size of a hole and the size of the shaft to be fitted to

that hole are indicated by the same standard size and different

tolerances of the hole and shaft. The tightness of fit is decided

by the tolerance.

•

Indication of size of rotating shaft and hole and relationship

drawing of them.

•

Example:

Standard size

Tolerance

120

–

0.022

–0.126

Example:

Standard size

Tolerance

Shaft

Hole

60

–0.030

–0.076

+0.046

+

0