DEFINED LIFE PARTS LIST

No.

Periodical replacement parts

Replacement interval

1

Fuel system

Fuel hose

Spill hose

Every 2 years or 4000 hours,

whichever comes sooner

Ask your Komatsu distributor

for replacement.

2

Engine lubrication system

Turbocharger lubrication hose

Engine oil filter hose

3

Work equipment hydraulic

system

Main pump delivery hose

Pump branch hose

Main pump LS hose

Hydraulic drive fan hose (Intake fan)

External work equipment hose

•

Boom foot connection hose

•

Boom cylinder hose

•

Arm connection hose

•

Arm cylinder hose

•

Bucket cylinder hose

•

Line hose for additional attachment

4

Others

PPC accumulator

Attachment additional accumulator

METHOD FOR CHECKING WATER PUMP

Check for leakage of water and oil around the water pump. If any problem is found, ask your Komatsu distributor

to perform disassembly, repair, or replacement.

CHECK OPERATING CONDITION OF COMPRESSOR

Ask your Komatsu distributor for inspection.

METHOD FOR CHECKING STARTING MOTOR

Ask your Komatsu distributor to have the starting motor checked.

If the engine is started frequently, have this inspection performed every 1000 hours.

METHOD FOR REPLACING ACCUMULATOR (FOR CONTROL CIRCUIT)

k

k

WARNING

The accumulator is charged with high-pressure nitrogen gas, and improper operation may cause an ex-

plosion which will lead to serious injury or death. When handling, always observe the following.

• The pressure in the hydraulic circuit cannot be completely removed. When removing the hydraulic

equipment, do not stand in the direction that the oil spurts out when performing the operation. In

addition, loosen the bolts slowly when performing the work.

• Do not disassemble.

• Do not bring open flame close to it or do not dispose of it in fire.

• Do not perform drilling, welding or flame-cutting.

• Do not hit or roll it, or subject it to any impact.

• When disposing of it, the gas must be released. Ask your Komatsu distributor to have this work per-

formed.

MAINTENANCE PROCEDURE

MAINTENANCE

4-74

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

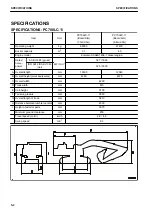

Страница 397: ...SPECIFICATIONS 5 1...

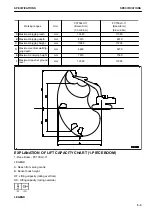

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...