3) Lock the hooks (2) diagonally, (top and bottom, right

and left) in the same way as when tightening the bolts.

4) Always install the cover (3) so that the vacuator valve

(4) faces right below (A).

5) When the cover (3) is installed, check that the clear-

ance between the air cleaner body and cover (3) is not

too large. If the clearance is too large, install it again

correctly.

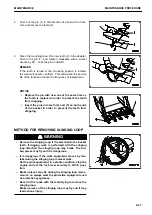

10. After replacing the element, press the reset button (9) of

dust indicator to return the yellow indicator plate to its origi-

nal position.

CHECK AND REPLACE VACUATOR VALVE

Check vacuator valve (4) for damage and deformation of its rubber portion.

If the vacuator is damaged or its rubber part is deformed, replace it with a new one.

METHOD FOR CLEANING INSIDE OF COOLING SYSTEM

k

k

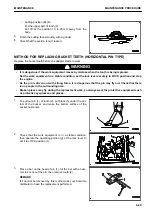

WARNING

• Immediately after the engine is stopped, the coolant is still hot and the pressure is accumulated in

the radiator. If the cap is removed under this condition and the coolant is drained, it may cause a

burn. Wait for the temperature to go down, and then turn the cap slowly to release the pressure.

• When starting the engine while cleaning the machine, set the lock lever in LOCK position to prevent

the machine from moving.

• When the undercover is removed, there is a danger of touching the fan.

Never enter the rear part of the machine when the engine is running.

• Never approach the fan at the front of the machine while the engine is running. There is a danger of

touching the fan.

• It is very dangerous to go under the machine for cleaning while the engine is running, since the ma-

chine may move unexpectedly. While the engine is running, never go under the machine.

Place the machine on a level ground when cleaning or changing the coolant.

Clean the inside of the cooling system, or change the coolant according to the table below.

Coolant

Cleaning of inside of cooling system and re-

placement of coolant

Non-Amine Engine Coolant

(AF-NAC)

Every 2 years or

4000 hours, whichever comes sooner

The coolant has the important function of preventing corrosion as well as preventing freezing.

Even in the areas where freezing is not an issue, the use of coolant is essential.

Komatsu machines are supplied with Non-Amine Engine Coolant (AF-NAC). Non-Amine Engine Coolant (AF-

NAC) has excellent anti-corrosion, antifreeze and cooling properties and can be used continuously for 2 years

or 4000 hours.

MAINTENANCE

MAINTENANCE PROCEDURE

4-21

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...