7.

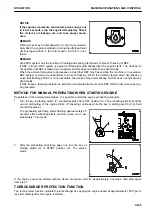

If the maintenance time has passed for certain items,

maintenance time caution lamp (17) is lit in red for 30 sec-

onds. Press switch F6, check the item, and perform main-

tenance immediately.

For details of the method of checking the maintenance in-

terval, see “MAINTENANE SCREEN SETTING” in EX-

PLANATION OF COMPONENTS.

METHOD FOR STARTING ENGINE

k

k

WARNING

• Start the engine only while sitting down in the operator's seat.

• Do not attempt to start the engine by short-circuiting the engine starting circuit.

Doing so may cause a serious personal injury or death or fire.

• Check that there are no persons or obstacles in the surrounding area, then sound the horn and start

the engine.

• Never use starting aid fluids as they may cause explosions.

• Exhaust gas is toxic.

When starting the engine in confined spaces, be particularly careful to ensure good ventilation.

NOTICE

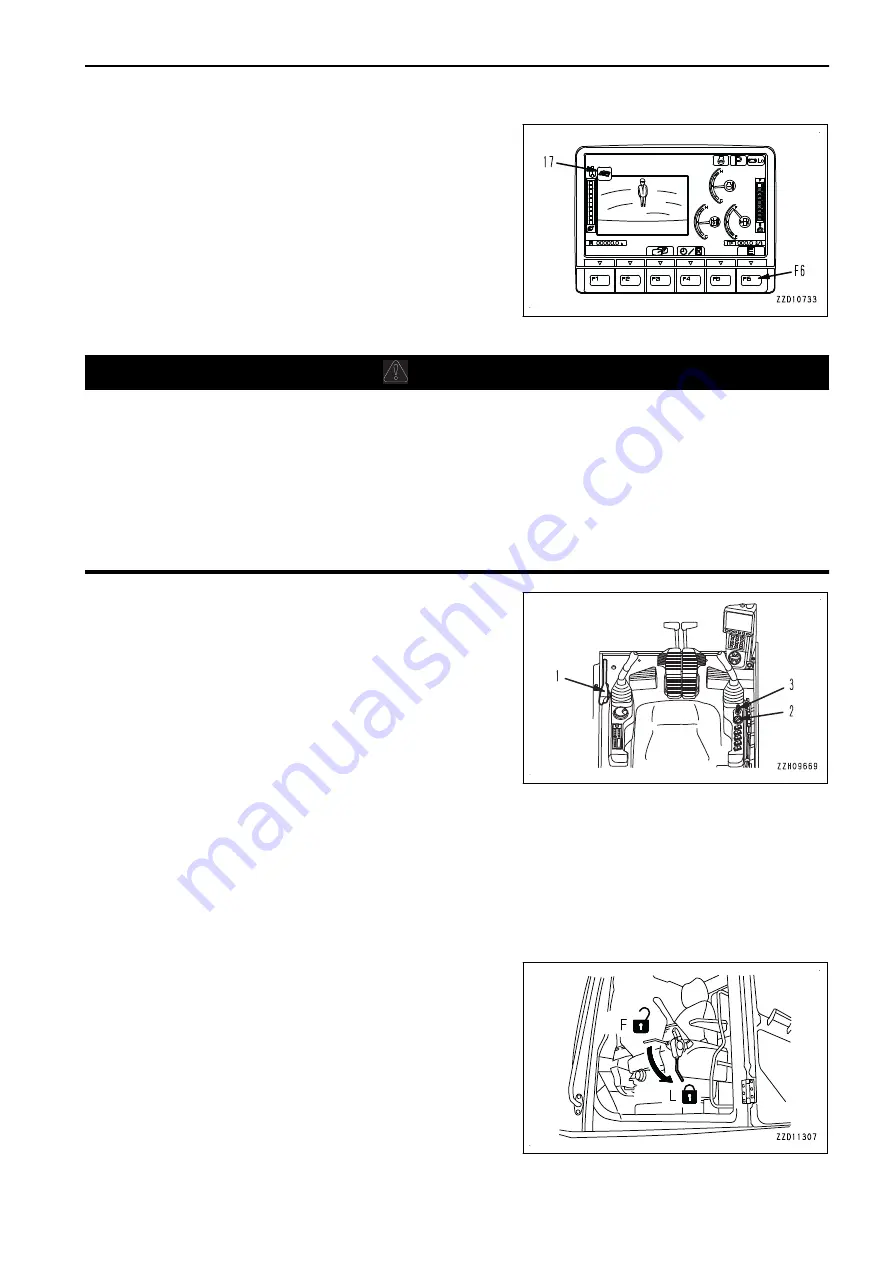

• Before starting the engine, check that fuel control dial

(2) is at Low idle (MIN) position. If the fuel control dial

is at High idle (MAX) position, the engine will acceler-

ate suddenly and cause damage to the engine parts.

• Do not keep the key in starting switch (3) at the START

position continuously for more than 20 seconds.

If the engine does not start, wait for at least 2 minutes,

then start again from the beginning.

• After the engine starts, wait for the engine oil pressure

caution lamp to go out. Do not touch the control levers

or control pedal while the engine oil pressure caution

lamp is lit.

This machine is equipped with an engine automatic preheating device that functions to start the engine preheat-

ing automatically.

When the ambient temperature is low, the preheating caution lamp lights up when the key in starting switch (3)

is turned to ON position to inform the operator that preheating has been started automatically.

Start the engine according to the following procedure.

1.

Check that lock lever (1) is at LOCK position (L).

If lock lever (1) is in FREE position (F), the engine does

not start.

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-163

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...