q)

Before making the final gas connection, thoroughly purge the gas

supply pipework to remove all foreign matter, otherwise serious

damage may be caused to the gas control valve on the fire

.

2.3

GAS TIGHTNESS AND INLET PRESSURE - MANUAL CONTROL

MODELS.

a)

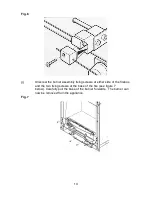

Remove the pressure test point screw from the inlet elbow and fit a

manometer.

b)

Turn on the main gas supply and carry out a gas tightness test.

c)

Depress the control knob and turn anti-clockwise to the position marked

pilot. Hold in the control knob for a few seconds to purge the pipe work

then press the igniter button. The burner should light, continue to hold

the control knob for a few seconds then turn to the full-on position.

d)

Check that the gas pressure is

20.0 mbar (+/- 1.0mbar) 8.0 in w.g.(+/-

0.4 in w.g.)

e)

Turn off the fire, remove the manometer and refit the pressure test point

screw. Check the pressure test point screw for gas tightness with the

appliance turned on using a suitable leak detection fluid or detector.

2.4

GAS TIGHTNESS AND INLET PRESSURE - SLIDE CONTROL

MODELS.

a)

Remove the pressure test point screw from the pressure test point and

fit a manometer.

b)

Turn on the main gas supply and carry out a gas tightness test.

c)

Depress the control lever to the position marked pilot. Hold down the

control lever for a few seconds to purge the pipe work. The burner

should light, continue to hold the control lever for a few seconds to latch

the valve then lift to the full-on position.

d)

Check that the gas pressure is

20.0 mbar (+/- 1.0mbar) 8.0 in w.g.(+/-

0.4 in w.g.)

e)

Turn off the fire, remove the manometer and refit the pressure test point

screw. Check the pressure test point screw for gas tightness with the

appliance turned on using a suitable leak detection fluid or detector.

18