124

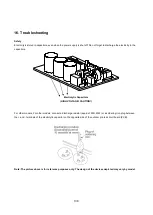

2.2 Power on and let the air conditioner

operate for cooling. Check operation status

of drainage pump, and then connect the

plug of water level switch, check the

operation sound of water pump and

observe whether the water can discharge

through the transparent hard pipe at

drainage outlet. (In light of the length of

drainage pipe, water shall be discharged

about 1 minute delayed)

2.3 Stop the operation of air conditioner, power

off the power supply and put the cover of

water test hole back to the original place.

a. After stopped the air conditioner 3 minutes,

check whether there is anything abnormal.

If drainage pipes have not been distributed

properly, over back-flow water shall cause

the flashing of alarm indicator at

remote-controlled receiving board and

even water shall run over the water

collector.

b. Continuously infusing water until water

level alarmed, check whether the drainage

pump could discharge water at once. If

water level does not decline under warning

water level 3 minutes later, it shall cause

shutdown of unit. When this situation

happens, the normal startup only can be

recovered by turning down power supply

and eliminating accumulated water.

Note:

Drain plug at the main water-containing

plate is used for eliminating accumulated water

in water-containing plate when maintaining air

conditioner fault. During normal operation, the

plug shall be filled in to prevent leakage.

13.5.4 Insulation work of drainage pipe

Refer the introduction to the insulation

engineering parts.

13.6 Vacuum Drying and Leakage Checking

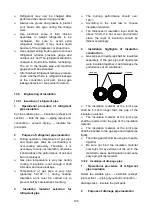

13.6.1 Purpose of vacuum drying

Eliminating moisture in system to prevent

the phenomena of ice-blockage and copper

oxidation.

Ice-blockage shall cause abnormal

operation of system, while copper oxide

shall damage compressor.

Eliminating the non-condensable gas (air)

in system to prevent the components

oxidizing, pressure fluctuation and bad heat

exchange during the operation of system.

13.6.2 Selection of vacuum pump

The ultimate vacuum degree of vacuum

pump shall be -756mmHg or above.

Precision of vacuum pump shall reach

0.02mmHg or above.

13.6.3 Operation procedure for vacuum

drying

Due to different construction environment, two

kinds of vacuum drying ways could be chosen,

Содержание KDIP012-H2

Страница 8: ...5 2 2 Part names of Indoor Outdoor units Cassette Units ...

Страница 9: ...6 KDIR Duct Units ...

Страница 10: ...7 KDIP Duct Units ...

Страница 11: ...9 Ceiling floor Units ...

Страница 12: ...10 HESP DUCT Units ...

Страница 19: ...19 2 3 4 7 Outside Water Pump for Optional When Ceiling Installation ...

Страница 31: ...33 KSIE024 H220 O KSIR036 H218 inch 37 2 16 1 31 9 40 6 26 5 15 9 ...

Страница 34: ...36 Ceiling floor Units ...

Страница 39: ...41 KTIR036 H2G1 KTIR048 H2G1 ...

Страница 40: ...43 KUIR18 H2 KUIR24 H2 ...

Страница 41: ...44 KFUF036 H2G1 KFUF048 H2G1 ...

Страница 42: ...45 KFUF060 H2G1 ...

Страница 43: ...46 KFUF036 H2G1 KFUF048 H2G1 ...

Страница 44: ...47 KDIP090 H2 KDIP012 H2 KDIP018 H2 KDIP24 H2 ...

Страница 69: ...74 6 2 Outdoor Unit KSIE018 H220 O KSIE024 H220 O ...

Страница 70: ...75 KSIE009 H221 O KSIE012 H220 O ...

Страница 71: ...77 KSIR036 H218 ...

Страница 77: ...83 KDIR09 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 78: ...84 KDIR12 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 79: ...85 KDIR18 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 80: ...86 KDIR24 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Страница 96: ...104 12 Field Wiring 9K 24K 36K 48K 60K ...

Страница 97: ...105 ...

Страница 147: ...155 P U P V ...

Страница 148: ...156 P W P N ...

Страница 174: ...184 4 Remove the evaporator support board 5 Screw off the fixing screws to remove the evaporator 4 screws 1 screw ...

Страница 181: ...191 4 Remove the evaporator fixing clamps to disassemble the evaporator Fixing clamps 1 screw ...

Страница 188: ...221 5 Remove the four fixing screws of the fan motor then remove the motor 5 ...

Страница 201: ...234 6 Remove the grounding screw 7 Remove the Wires 1 2 3 or L1 L2 S Then remove the electronic control box 7 5 ...