19

3.

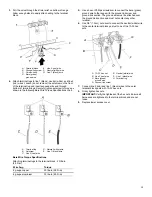

Pull the wires through the strain relief on bottom of range.

Allow enough slack to easily attach wiring to the terminal

block.

A. Terminal block

B. Ground-link screw

C. Cord/conduit

D. Bare (green)

ground wire

E. Line 2 (red) wire

F. Nautral (white) wire

G. Line 1 (black) wire

4.

Attach terminal lugs to line 1 (black), neutral (white), and line 2

(red) wires. Loosen (do not remove) the setscrew on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten setscrew to torque as

shown in the following Bare Wire Torque Specifications chart.

A. Terminal lug

B. Setscrew

C. Line 2 (red) wire

D. Natural (white) wire

E. Line 1 (black) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in

(2.3 N-m)

Wire Awg

Torque

8 gauge copper

25 lbs-in (2.8 N-m)

6 gauge aluminium

35 lbs-in (4.0 N-m)

5.

Use a hex or Phillips screwdriver to connect the bare (green)

ground wire to the range with the ground-link screw and

ground-link section. The ground wire must be attached over

the ground-link section and must not contact any other

terminal.

6.

Use 3/8" (1.0 cm) nut driver to connect the neutral (white) wire

to the center terminal block post with one of the 10-32 hex

nuts.

A. 10–32 hex nut

B. Line 2 (red) wire

C. Bare (green)

ground wire

D. Ground-link screw

E. Neutral (white) wire

F. Line 1 (black) wire

G. Terminal lug

7.

Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

8.

Firmly tighten hex nuts.

IMPORTANT:

Verify the tightness of the hex nuts. Ensure all

harnesses are tightened to the terminal block and are not

loose.

9.

Replace lower access cover.