Installation and initial operation

46

01.04.2020

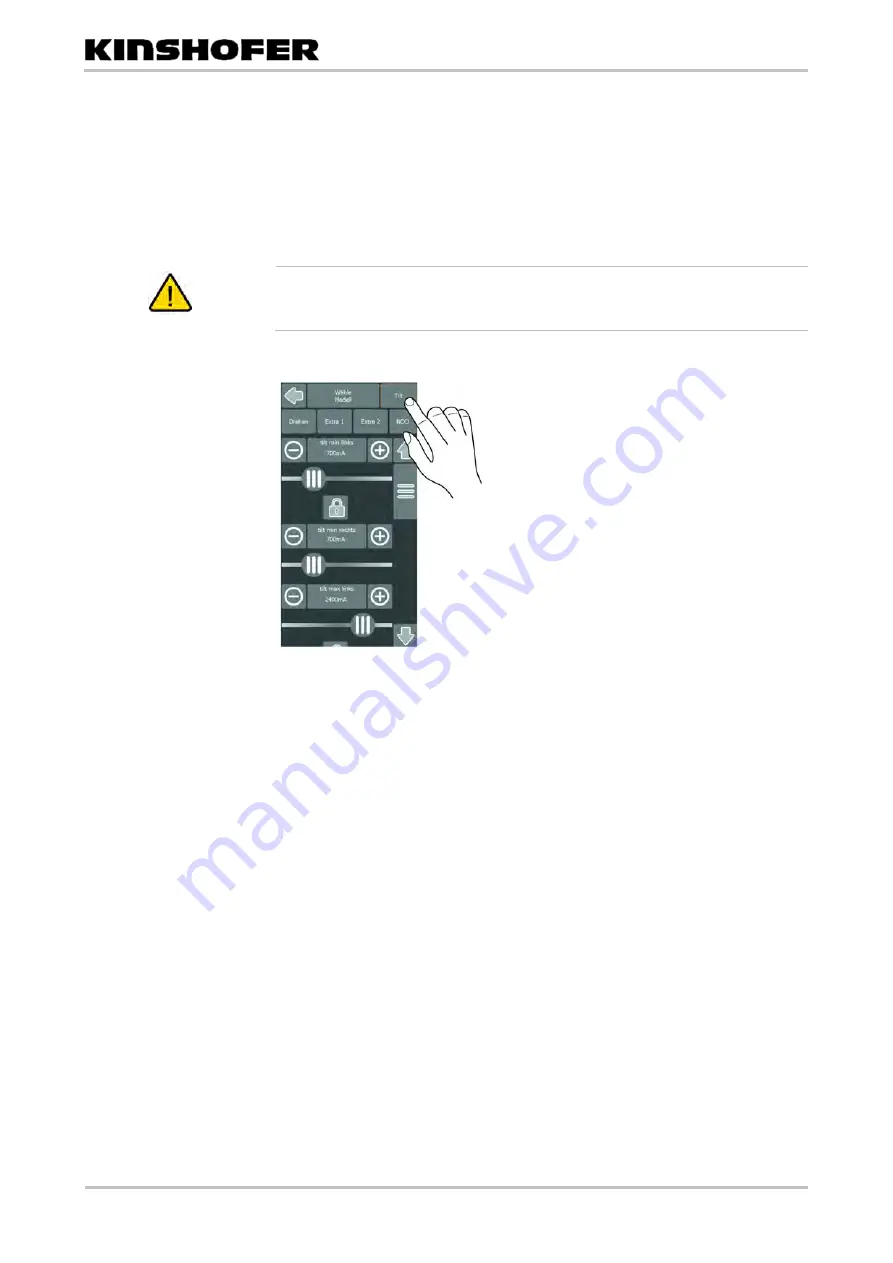

The duty cycles of the PWM signals are pre-configured for each NOX model, but

these may be adjusted as required.

Minimal duty cycle: The valve coils require a minimum electrical potential to open.

If the minimum is set too low, a long dead time will result. This means that the

function will only start once the joystick is seriously deflected.

Maximum duty cycle: Normally, valves have the highest oil flow at 90% duty

cycle, i.e. 90% is the ideal maximum duty cycle. If the maximum speed is reduced

and more linear movement results, the maximum duty cycle may be reduced.

WARNING

Risk of serious injuries through unexpected tilting or rotating of the tiltrotator!

•

Only allow correspondingly trained personnel to adjust the duty cycle.

1. Tap the

Tilt

,

Rotate

,

Extra 1

,

Extra 2

and

NOO

buttons.

2. In each case, adapt the minimum and maximum duty cycle.

3. Tap the

Select model

button and select the NOX model anew to reset the

settings to the standard values.

4.2.7.

Carrying out automatic calibration

If the tiltrotator has a rotation sensor, automatic calibration can be carried out.

The valve values for the tilting, rotating and for the pressure reduction valve are

automatically set during automatic calibration.

1. If the pressure reduction valve used is not standard, ensure that the type of

pressure reduction valve is set, see "Setting the pressure reduction valve".

Adjust the duty cycle of

the PWM signals