Installation/Operation/Maintenance

Direct-activated Pressure

Relief/Sustaining/Back Pressure Valve

Installation/Operation/Maintenance Manual

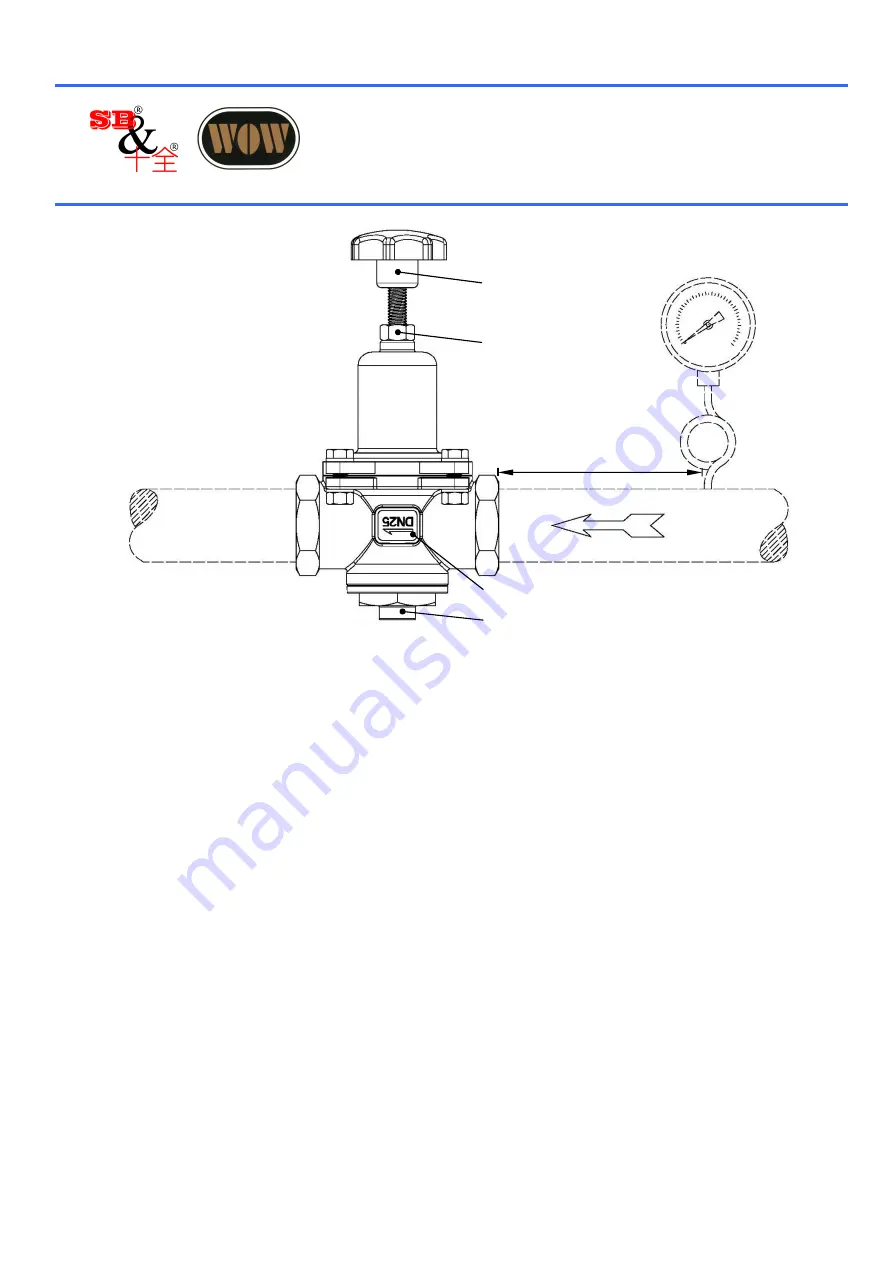

1. Installation

a) Confirm the valve is suitable for the system, such as media, function, pressure, etc.

b) Before installation, the pipe of the system must be cleaned, and no fragment or any

garbage is allowed in the pipe.

c) Before the inlet of the valve, a strainer is needed; this can make the valve work properly.

d) Two shutoff valves can be installed at the inlet and the outlet of the valve, which will

facilitate the maintenance of the valve. Upstream of the valve to be installed at more than

five times the diameter pressure gauge to read the line pressure.

e) Following the arrow direction when installing the valve, and the arrow direction must be

conform to the flow direction.

f) The valve can be installed horizontally or vertically, and the maintenance space must be

held.

g) A pressure gauge or a plug (connected with PT1/8" thread) can be installed in the port of

PT1/8" in Fig.1.

Model: 72

Adjusting Screw

Locking Nut

Flow

Size/Flow Direction

PT1/8”

5D

Fig.1