11

WORKING CONDITIONS

The hydraulic turning device, or rotator, is designed for use on a hydraulically-powered

lifting crane, e.g. cranes that handle timber or single items. The rotator axle is fitted to lifting

equipment, e.g. a grapple, which grips the load. The load can be rotated horizontally using

the rotator. The hydraulics are connected to the lifting equipment through the rotator axle.

The maximum permissible load on the lifting equipment must not exceed the corresponding

value for the rotator. When the rotator is in use, the hydraulic oil must be at the correct working

temperature and satisfy standard viscosity values.

INSTALLATION INSTRUCTIONS

•

Rotator connection to the crane

•

The rotator must be connected to the end of the crane boom using a link.

•

The rotator must always be suspended freely and vertically in the direction of the axle.

The link pins must be locked in place using clip pins.

•

The rotator is connected to a bushing on the lifting equipment using a pin that is locked

in place with clip pins.

CONNECTING THE ROTATOR TO THE CRANE HYDRAULIC SYSTEM

Turning the rotator

: The system should be thoroughly cleaned. Once the hydraulic system

has reached working temperature, the oil should be circulated to channel any impurities to the

filter. The hoses for the rotator's turning unit are connected together using intermediary nipples

before the rotator. Oil can circulate in this line for at least 5 minutes. The rotator is connected

to the crane's control valve via suitable hoses and pipes. The crane must be equipped with

pressure-limiting valves that limit the pressure going to the rotator to a maximum of 200 bar. If a

higher pressure is possible, pressure-limiting valves should be installed on the rotator's hydraulic

line. The oil flow for rotator rotation is regulated using control nipples. The rotational direction

of the rotator and grapple movement must correspond to the markings on the control levers. If

rotation is too slow, the rotator's movement speed must be checked. Control nipple openings

have been factory-set to a diameter of 1.5 mm. They can be enlarged in 0.1 mm increments.

ROTATOR LEAD-THROUGH

When connecting the hydraulics, it should be noted that the maximum pressure in the

pressure duct is 200 bar and that the marked duct in the rotator's upper cover (upper duct)

and the axle must be linked to the opening side of the cylinder on the lifting equipment, e.g.

a grapple. When the grapple opens, it should be noted that the cylinder movement does not

extend fully to keep the duct under pressure as this pressure is an unnecessary load on the

rotator. The crane and equipment must be compliant with the Machinery Directive.

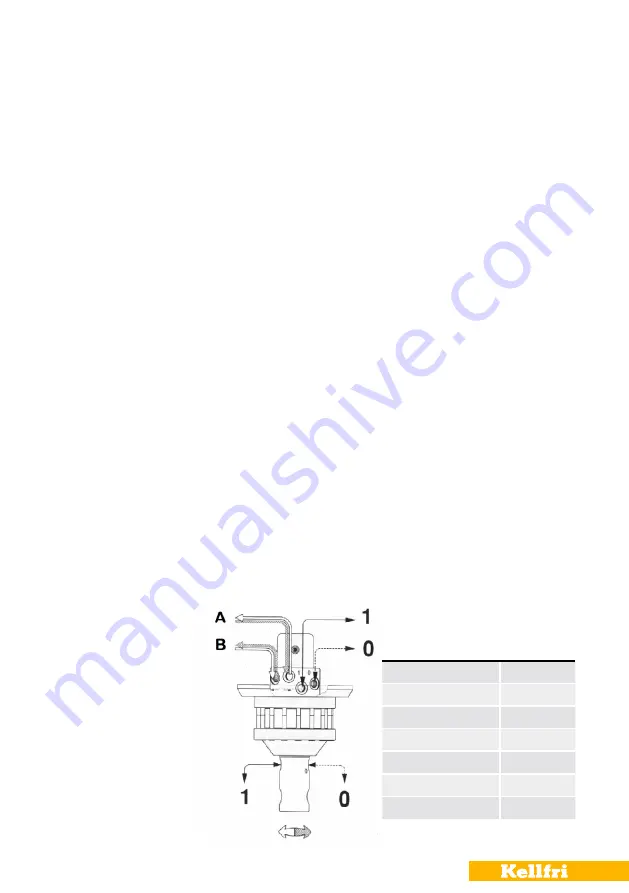

A, B = Reverse flow

1 = Grapple loader closed

0 = Grapple loader open

Technical data

KR07

Turning angle

Unlimited

Max. operating pressure

200 bar

Rec. l/min.

10

Torque (200 bar)

350 Nm

Max. axial force

20 kN

Max. permissible load

1000 kg

Weight

17 kg

Содержание 21-GL36

Страница 19: ...19 Table of Contents 21 GL36 PINS 21 GL36 BUSHINGS...

Страница 25: ...25 Table of Contents 21 GL47 BUSHINGS 21 GL47 PINS...

Страница 34: ...34 Table of Contents NOTES...