1-18 (No.YF079)

SECTION 5

TROUBLE SHOOTING

5.1

SERVICE NOTE

Sy

m

b

o

l No

.

R

e

m

o

ving order of screw

Place to stick screw

R

eference drawing (Fig.No.)

Screw tightening torque

Sy

m

b

o

l No

.

R

e

m

o

ving order of screw

Place to stick screw

R

eference drawing (Fig.No.)

Screw tightening torque

R

e

m

o

ving order of screw

Place to stick screw

R

eference drawing (Fig.No.)

Screw tightening torque

[1]

[2]

FA1

FA2

FA3

FA4

FA5-2

FA5-1

123456789

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

㧖㧖

㧖

㧖

㧖

㧖

㧖

㧖

㧖

㧖

㧖

㧖㧖

㧖㧖

㧖

㧖

[3]

[6]

[7]

[4]

[5]

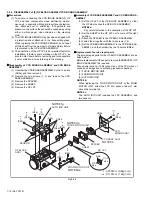

CABINET PARTS AND ELECTRICAL PARTS(1)

12

123456789

1

0

1

1

3-2-3-2

3-2-3-3

3-2-3-1

[3]

[3]

MONITOR ASSY

NOTE:

a

d

FA5-1

FA6

[10]

[11]

[12]

[13]

21

22

23

24

25

26

28

27

㧖

㧖㧖㧖㧖㧖㧖㧖

㧖

㧖㧖

㧖

[8]

[9]

FA7

FA8

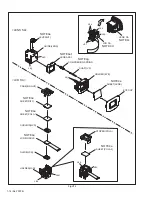

CABINET PARTS AND ELECTRICAL PARTS(2)

ab

c

a

R

e

m

o

ving order of screw

Place to stick screw

R

eference drawing (Fig.No.)

Screw tightening torque

12345

VF1

[4]

[4]

VF ASSY

123456789

1

0

1

1

3-2-4

[8]

[8] O

P BLOCK ASSY / CCD BOARD ASSY

NOTE:

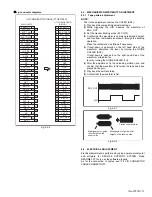

㧝㧖

(This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the

screws from loosening.

Prepare the specified screws and use them in place of the removed screws.

㧞

Tightening torque for the screws

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough

measurement (reference value),

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque

value in the assembling procedure.

Be careful not to break either the screws or the screw holes.

ޓ

a

㧦

0.092N

㨯

m (0.94kgf

㨯

cm

)

ޓޓ

b

㧦

0.078N

㨯

m (0.8kgf

㨯

cm)

ޓޓ

c

㧦

0.069N

㨯

m (0.7kgf

㨯

cm)

ޓޓ

d

㧦

0.098N

㨯

m

(1.0kgf

㨯

cm)

ޓޓG㧦

0.118N

㨯

m (1.2kgf

㨯

cm)

c

e

b

㧖

18

19

20

-

-

-

-

-

-

-

-

-