9

ADJUSTING INSTRUCTIONS

Instructions stating direction or location, such as right, left, front or rear of the machine are given relative to

the operator's position at the machine unless otherwise noted. The handwheel rotates clockwise in

operating direction.

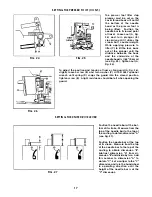

SETTING THE NEEDLE BAR HEIGHT & ALIGNMENT

Insert the first (left) and fourth needles into the needle head. The

needles for this Class of machine are made with two flats on the front

of the shank. This will enable you to correctly position the needles in

the needle head. Make certain the needle shank is fully inserted and

that the screw is seated firmly on the flat.

To position the needle head square with the throat plate, use the

upper knife or a straight edge to align the needles with the cross

grooves in the throat plate. (See Fig. 2)

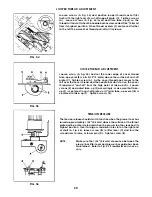

Refer to table 1 for the dimension from the fourth (lowest) needle to

the surface of the throat plate and for the number of the needle bar

height gauge.

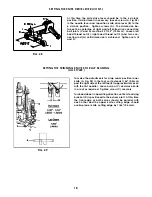

Position the needle bar at its highest

point of travel. Loosen needle bar

clamp screw (A, FIG.3) & use the speci-

fied needle bar height gauge (B) to

achieve the desired height dimension

from the fourth (lowest) needle (C) to

the throat plate surface (D). Tighten

clamp screw (A) and recheck setting.

Care must be taken not to disturb the

needle head alignment while making

the adjustment. Add the two middle

needles and the retainer.

CAUTION: If the needle head has been replaced it must be torqued to 17 in. lbs.

(20cm/kg). After tightening, check for expansion of the needle bar by position-

ing it up into the lower bushing hole. If the bar has expanded it will bind in the

bushing. The bar must be replaced or lapped to reduce the bell shape. Align

and set needle bar height as described above.

FIG. 2

TABLE 1

FIG. 3

E

L

Y

T

S

M

O

R

F

N

O

I

S

N

E

M

I

D

)

T

S

E

W

O

L

(

H

T

4

O

T

E

L

D

E

E

N

E

T

A

L

P

T

A

O

R

H

T

E

C

A

F

R

U

S

E

L

D

E

E

N

R

A

B

T

H

G

I

E

H

E

G

U

A

G

R

E

B

M

U

N

E

L

D

E

E

N

T

H

G

I

E

H

E

G

U

A

G

P

E

T

S

D

E

K

R

A

M

E

G

U

A

G

2

5

)

M

M

5

.

3

1

(

"

2

3

/

7

1

U

B

7

2

2

1

2

1

3

5

.

E

G

U

A

G

0

6

)

M

M

7

.

2

1

(

"

2

/

1

S

D

7

2

2

1

2

0

0

5

.

Содержание UnionSpecial 36200UAD52

Страница 7: ...7 THREADING 36200 0 0 MACHINE...

Страница 22: ...22 9 16...

Страница 24: ...24 2 31 18 17 14 ____ 12 19 4 3...

Страница 26: ...26 3...

Страница 28: ...28 21 T19DRQUE TO 21 22 241n lbs cm kg I...

Страница 30: ...30 15 12 6 j 38 I I 44 37 28...

Страница 40: ...40 4 40 i li l rrrt l 1 i r C J 4 12 2 27 32 172 2mml 3 5 32 180 2mmJ...

Страница 44: ...44 16 27 Torque to 18 rt lbso I...

Страница 46: ...46 11 3...

Страница 48: ...48 1 17A...

Страница 50: ...50...

Страница 52: ...52 2 4 4 5 8 9 10 20 15 21 25...

Страница 56: ...56 1 4...

Страница 58: ...58 17 18 8 7 6...

Страница 60: ...60 5 I I I 10 8 I I I gi I L I I I I I j J...