– 7 –

– 7 –

‒ 7 ‒

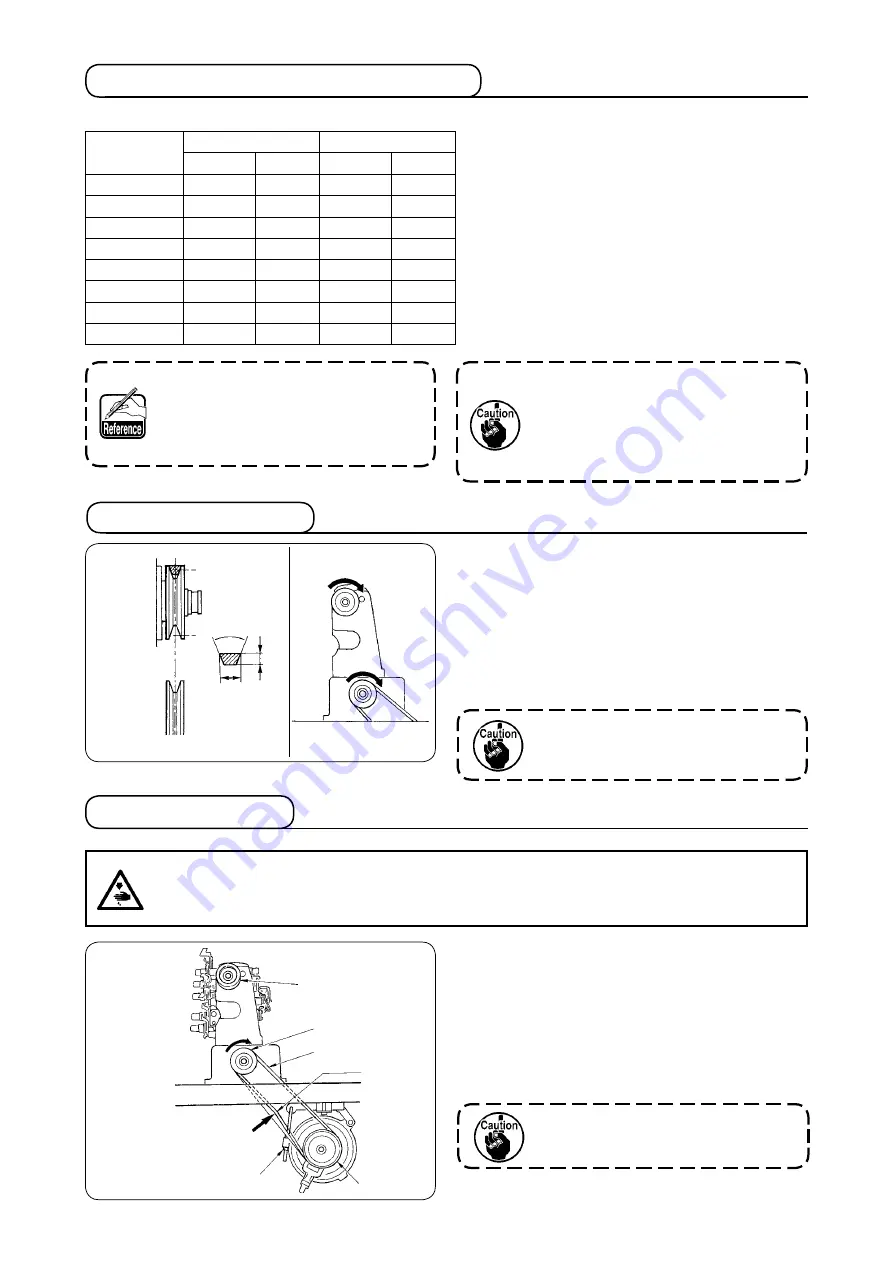

2. Selecting the motor pulley and the belt

* The table shows the numbers when a 3-phase

2-pole 400 W clutch motor (1 / 2 HP) is used.

* The commercially-available motor pulley near to

the counted value is designated since the outside

diameter of the commercially-available motor pulley

counts by 5 mm.

Use a motor pulley which is adaptable to

this sewing machine. The sewing speed

exceeds the max. sewing speed of this

sewing machine and machine trouble will

be caused unless a motor pulley which is

adaptable to this sewing machine is used.

When you use a new sewing machine, use

the machine at a speed of 4,500 sti/min or

less for the first 200 hours (approximately

one month). A good result can be obtained

in terms of the durability.

Motor pulley and belt

Speed of

stitch

(sti/min)

50Hz

60Hz

Pulley size

Belt size

Pulley size

Belt size

4,500

ø 100

M-35

ø 85

M-35

4,800

ø 105

M-36

ø 90

M-35

5,000

ø 115

M-36

ø 95

M-35

5,500

ø 125

M-37

ø 105

M-36

5,800

ø 130

M-37

ø 110

M-36

6,000

ø 135

M-37

ø 115

M-37

6,200

ø 140

M-38

ø 120

M-38

6,500

ø 150

M-39

ø 125

M-38

3. Installing the motor

Motor pulley

5.5

mm

10 mm

M type V belt

Use a clutch motor of 3-phase, 2-pole, 400 W (1/2HP).

Use the M type V belt.

1) The motor pulley shifts to the left-hand side when de

-

pressing the pedal. At this time, install the motor so

that the centers of motor pulley and lower pulley align

with each other.

* For the installing procedure of the motor pulley, refer to

the Instruction Manual for motor.

Lower pulley

2) Install the motor so that the pulley rotates clockwise.

If the machine pulley rotates in the reverse

direction, nomal lubrication cannot be per-

formed. As a result, machine trouble will

be caused.

4. Setting the belt

WARNING :

When replacing the belt, be sure to turn OFF the power to the motor and ascertain that the motor has

totally stopped rotating before starting the work. There is a danger of injury since hands or clothes may

be caught in the belt.

1) Fit belt

❶

to lower pulley

❷

.

2) Turning upper pulley

❸

, set the other side of the belt to

motor pulley

❹

.

3) Adjust the belt tension so that the belt sags 15 to 20

mm when the center of the belt is pressed with an ap

-

proximate 10N (1.02 kgf) load.

4) Securely fix the belt with lock nut

❺

when the belt has

been set.

❶

❸

❹

❺

❷

15 - 20 mm

If the deflection of the belt is excessive

when the sewing machine is operated,

check again the belt tension.

40˚

Содержание MF-7500 Series

Страница 1: ...i ENGLISH INSTRUCTION MANUAL MF 7500...