JOHNSON CONTROLS

11

SECTION 2 - INSTALLATION

FORM 160.43-NM4

ISSUE DATE: 11/12/2012

2

WIRING

Disconnect all supply circuits before wir-

ing LPCO control.

Wire control according to national and

local electrical codes. Maximum wire size

is #14 awg.

The recommended tightening torque for

field wiring terminals is 7 to 17 in-lbs.

Electrical ratings stated in literature and

on nameplates must never be exceeded -

overload on a switch can cause failure on

the first cycle.

A 7/8 in. dia. hole for conduit connection is provided

on the left hand side of the bracket plate. Refer to Fig-

ures 2 and 3.

Keep the wires as short as possible to prevent inter-

ference with the plunger or the adjustable differential

switch wheel or obstructing enclosure cover closure.

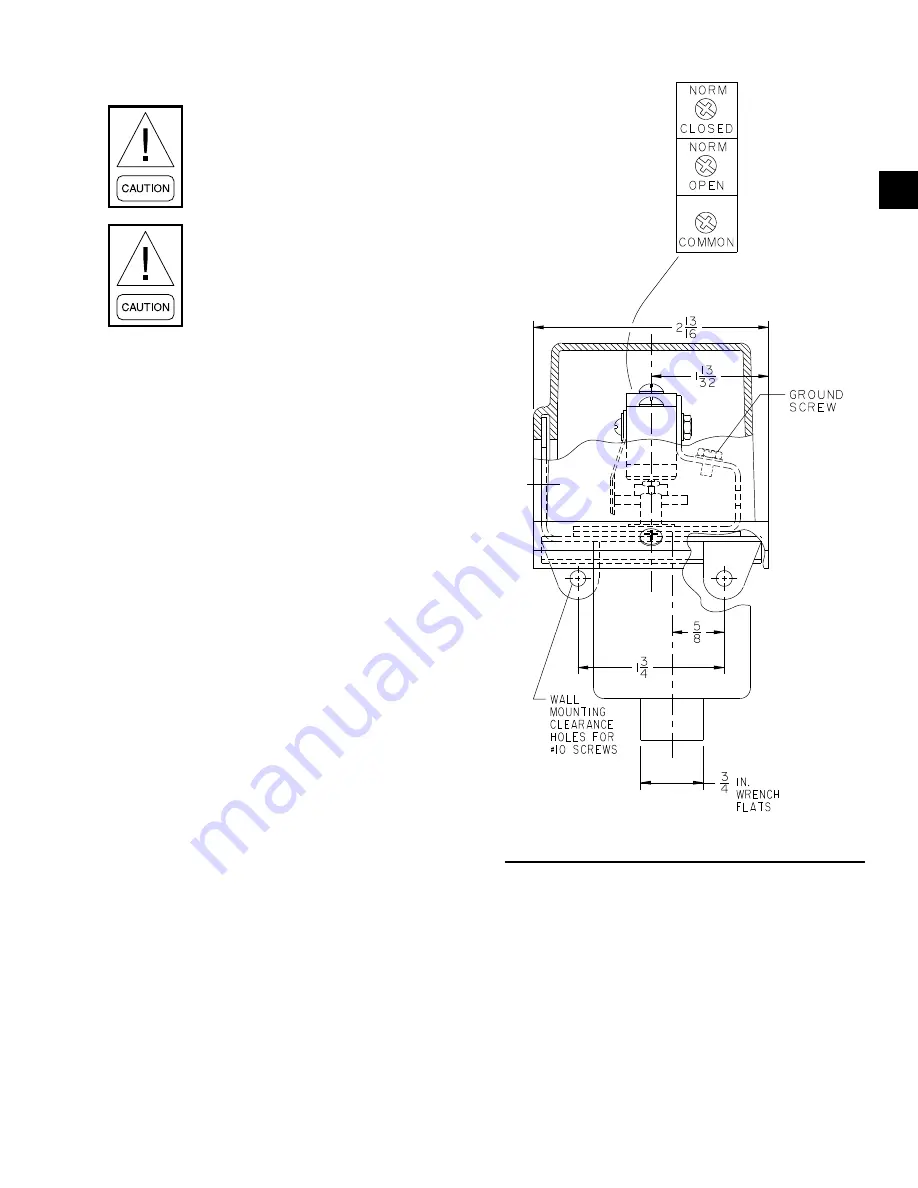

A grounding screw (green) is provided on the right

hand side at the rear of the switch bracket. Refer to

Figure 3.

The three switch terminals are clearly labeled COM-

MON, NORMALLY OPEN and NORMALLY

CLOSED. Refer to Figures 3 and 4.

1.

Remove enclosure cover first by removing the one

captive screw located on the front of the cover.

Refer to Figures 2 and 3.

2. Install kit supplied plastic snap bushing (YORK

p/n 025 10147 000) into 025 45742 LPCO control

7/8 in. dia. conduit hole. Refer to Figures 2 and 3.

3. Replacing a former 225 15443 002 LPCO control.

Proceed to step 4 if replacing a 025 45742 LPCO

control

a. To reach the LPCO control 025 45742 switch

terminals, the preexisting wires (47, 48 and

49) may need to be relocated through the

cabinet middle conduit fitting containing the

high pressure control wires. Reroute LPCO

wiring as necessary.

FIGURE 3 -

PRESSURE CONTROL FRONT VIEW

LD12523

b. The Faston type push-on terminal connectors

used with the former 225 15443 002 LPCO

control wiring are to be cut off and replaced

with kit supplied crimp-on insulated spring

spade (YORK p/n 025 18732 000) terminal

connectors.