JOHNSON CONTROLS

231

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

8

VSD OPERATION AND CONTROLS

VSD Logic Board

The VSD Logic Board communications with the Chill-

er Control Board via comms and controls the VSD

functions. It converts the frequency and run commands

from the Chiller Control Board into the necessary volt-

age and frequency commands to operate the inverter

section. It also controls the converter section of the

drive (AC Line to DC Bus conversion) by controlling

the pre-charge function.

The VSD Logic Board contains a 2nd microprocessor

(motor controller) that generates the PWM signals that

control the IGBT outputs in the inverter section of the

VSD.

An FPGA handles the hardware safeties that can shut

down the VSD much faster than the software safeties.

The VSD Logic Board handles all of the VSD related

safeties, which includes motor current, BUS voltage,

and other safeties.

The VSD Logic Board reports shutdown information

back to the Chiller Control Board via the RS-485 com-

munication link.

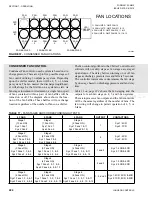

2, 3 and 4 compressor chillers all use the same soft-

ware. The microprocessor determines whether the

chiller is a 2, 3 or 4 compressor chiller by electroni-

cally checking for a factory-installed jumper in the sys-

tem wiring harness. The microprocessor checks for the

jumper located in the J1 plug wiring harness at power-

up. If no jumper or more than one jumper is sensed, the

microprocessor will inhibit start-up. Details regarding

the location of the jumper are provided in

figuration Jumpers on page 207

VSD Start/run Initiation

Following a successful precharge of the DC Bus and

a run command from the Chiller Control Board, the

VSD Logic Board microprocessor will determine the

motor output voltage (% modulation) and the output

frequency required based on the operating frequency

command from the Chiller Control Board. This infor-

mation will then be sent to the PWM generator located

on the VSD Logic Board.

On start-up, the output frequency from the VSD to the

motor(s) will be increased from 0 Hz to the operating

frequency commanded by the Chiller Control Board.

The rate of change of the frequency will also be con-

trolled by the VSD Logic Board.

The rate of change of the output frequency at start-up,

during acceleration is 10 Hz/sec between 0 and 50 Hz

and 30.4 Hz/sec above 50 hertz. The maximum rate

of change of the output frequency during deceleration

between 200 and 100 Hz is 30.4 Hz/sec, and 100 and 0

Hz is 10 Hz/sec.

The VSD Logic Board and its PWM generator will re-

ceive operating frequency and voltage commands from

the Chiller Control Board based on the load.

When a frequency (speed) change is requested from

the Chiller Control Board, the chiller microprocessor

will send the change to the VSD Logic Board and the

VSD Logic Board will acknowledge it accepted the

change. Loading and unloading will take place at the

rate of 0.1 to 1Hz every 2 seconds.

PWM Generator Type and Carrier Frequency

The PWM generator is responsible for providing asym-

metrical uniform sampled PWM waveforms to the

compressor motor at a carrier frequency of 3125 Hz by

turning on an off the inverter IGBT’s. The waveform

generated is equivalent to a specific V/F ratio at a given

speed based on the voltage and frequency commands

from the Chiller Control Board. The PWM Generator

receives operating frequency and voltage commands

from the VSD Logic Board control processor.

Short Circuit Protection Minimum Output

Pulse Width and Interlock Delay

The PWM generator is programmed to drop all “on”

pulses in less than 10 microseconds (and all matching

“off” pulses in the mirrored waveform) to permit time

for the IGBT gate drivers to detect and self extinguish

an inverter short circuit condition.

Modulating Frequency

The modulating frequency range will range from 0 to

200 Hz. The modulating frequency waveform con-

sists of a sinusoidal waveform summed together with

16.66% of the third harmonic component of the sinu-

soidal waveform. Utilization of this waveform as the

modulating waveform will permit the drive to generate

a fundamental line to line voltage equal to the DC Bus

voltage divided by 1.414.

SECTION 8 - MICROPANEL

Содержание YCIV0157

Страница 18: ...JOHNSON CONTROLS 18 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SAFETY SYMBOLS THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...JOHNSON CONTROLS 104 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SECTION 6 TECHNICAL DATA Panel Layout 2 Compressor Models ...

Страница 105: ...JOHNSON CONTROLS 105 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 115: ...JOHNSON CONTROLS 115 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 119: ...JOHNSON CONTROLS 119 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...