JOHNSON CONTROLS

169

SECTION 6 - TECHNICAL DATA

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

6

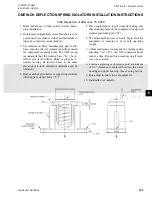

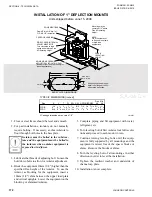

SLRS SEISMIC ISOLATOR INSTALLATION AND ADJUSTMENT

To Install and Adjust Mounts

1. Supports for mountings must be leveled to instal-

lation's acceptable tolerances.

2. Mountings not subjected to seismic or wind forces

do not require bolting to supports.

3. Mountings subjected to seismic or wind forces

must be bolted or welded in position.

4. If mountings are welded in position, remove low-

er friction pad before welding.

5. Set mountings with top channels held in place by

the lower restraining nuts and limit stops.

6. Place equipment on mountings and secure by

bolting or welding.

7. Hold lower restraining nut in place and turn ver-

tical limit stop bolt counter-clockwise until there

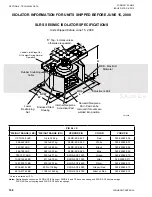

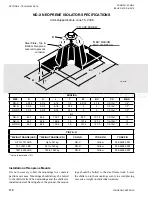

"D" Tap - 4 Holes unless

otherwise requested

Adjustment

Bolt

Vertical Limit

Stops-Out of

contact during

normal operation

Non-Skid Neoprene Pad-

Pad can be removed if

mounts are welded

into position.

Enclosed

Steel

Housing

Internal

Neoprene

Acoustical

Pad

Lower

Restraining

Nut

Rubber

Snubbing

Collar

MBD -Max

Bolt

Diameter

SHIPPED INSTALLED

A TER AD

STMENT

4"

"

LIMIT STOP

BOLT

LO ER

RESTRAININ

BOLTS

LD10568

Units shipped before June 15, 2008

is a 1/8" gap between the bolt head and the steel

washer.

8. Turn adjustment bolt 8 turns on each mount.

9. Take one additional complete turn on each adjust-

ment bolt in sequence until the top plate lifts off

of the lower restraining nuts. Take no additional

turns on that mount. Continue with equal turns on

the other mounts until the top plates lift off of the

lower restraining nuts of all mounts.

10. Hold the limit stop bolt in place and turn the low-

er restraining nut clockwise and tighten it against

the stanchion. Repeat the same procedure on all

mounts.

11.

Top plate should remain at a fixed elevation, plus

or minus 1/8".

Содержание YCIV0157

Страница 18: ...JOHNSON CONTROLS 18 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SAFETY SYMBOLS THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

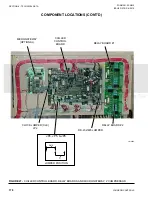

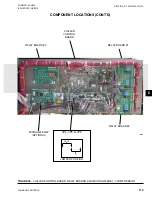

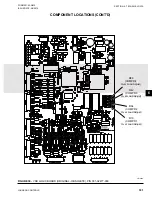

Страница 104: ...JOHNSON CONTROLS 104 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SECTION 6 TECHNICAL DATA Panel Layout 2 Compressor Models ...

Страница 105: ...JOHNSON CONTROLS 105 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 115: ...JOHNSON CONTROLS 115 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 119: ...JOHNSON CONTROLS 119 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...