5

Use Table 9 to assist in identifying the cause (s) of mal-

function in the MQL.

This table is intended as a diagnostic aid

only. For detailed repair procedures, con-

tact your ENVIRO-TEC ® representative.

TABLE 9 -

MQL TROUBLESHOOTING ANALYSIS

SYMPTOM

PROBABLE CAUSE

RECOMMENDED ACTION

BEARING IS EXCESSIVELY

HOT

First start after relubrication

(grease distribution).

Allow machine to cool down and restart.

Over-lubrication.

Clean surfaces of grease and purge.

Over tensioned belts.

Adjust belt tension.

No lubrication.

Apply lubricant. Check bearing for damage.

Misaligned bearing.

Correct alignment. Check shaft level.

MOTOR FAILS TO START

Blown fuse or open circuit

breaker.

Replace fuse or reset circuit breaker.

Overload trip.

Check and reset overload.

Improper wiring connections.

Check wiring with diagram supplied on unit.

Improper current supply.

Compare actual supply power with motor nameplate

recommendations. Contact power company for adjust-

ments.

Mechanical failure.

Check that motor and drive rotate freely. Check bear-

ing lubricant.

MOTOR STALLS

Open phase.

Check line for an open phase.

Overloaded motor.

Reduce load or replace with larger motor.

Low line voltage.

Check voltage across AC line. Correct voltage if pos-

sible.

EXCESSIVE VIBRATION

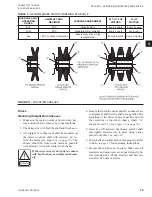

Poor alignment.

Align bearing setscrews (see Fig. 8). Loosen and

retighten bearing setscrew.

Shipping spacers not removed.

Remove shipping spacers and/or bolts.

Over tensioned belts.

Adjust belt tension.

Misaligned drive.

Align drive.

MOTOR RUNS AND THEN

DIES DOWN

Partial loss of line voltage.

Check for loose connections. Determine adequacy of

main power supply.

Stator shorts when motor warms

up.

Replace motor.

MOTOR DOES NOT COME

UP TO SPEED

Low voltage at motor terminals.

Check voltage across AC line and correct voltage loss

if possible.

Line wiring to motor too small.

Replace with larger sized wiring.

MOTOR OVERHEATS

Overloaded motor.

Reduce load or replace with a larger motor.

Motor fan is clogged with dirt.

Remove fan cover, clean fan and replace preventing

proper ventilation cover.

Temperature leaving heating sec-

tion is too high.

Increase airflow volume, reduce hot water inlet tem

-

perature, turn thermostat down.

SECTION 5 - TROUBLESHOOTING

JOHNSON CONTROLS

33

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013