SECTION 3 - CHASSIS & TURNTABLE

3-46

3121160

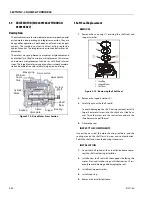

20.

Install orifice poppet (30).

21.

Install shift spool (31).

22.

Install spring retaining washers onto springs (32 and 33).

23.

Carefully install centering springs (34, 35, and 36).

24.

Install new o-rings (37, 38, and 39).

25.

Using a 5/8 in. wrench torque plug (40) to 20 ft. lbs.

(27 Nm).

26.

Using a 11/16 in. wrench, torque plugs (41 and 42) to

27 ft. lbs. (37 Nm).

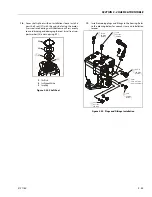

Initial Start-up Procedures

Follow this procedure when starting-up a new motor or when

installing a motor that has been removed.

Prior to installing the motor, inspect for damage incurred dur-

ing shipping. Make certain all system components (reservoir,

hoses, valves, fittings, heat exchanger, etc.) are clean prior to

filling with fluid.

1.

Fill the reservoir with recommended hydraulic fluid.

Always filter fluid through a 10 micron filter when pour-

ing into the reservoir. Never reuse hydraulic fluid.

2.

Fill the inlet line leading from the pump to the reservoir.

Check the inlet line for properly tightened fittings and

be certain it is free of restrictions and air leaks.

3.

Fill the pump and motor housing with clean hydraulic

fluid. Pour filtered oil directly into the upper most case

drain port.

4.

To ensure the pump and motor stay filled with oil, install

case drain lines into the upper most case drain ports.

5.

Install a 0 to 500 psi (0 to 35 bar) gauge in the charge

pressure gauge port of the pump to monitor system

pressure during start up.

6.

While watching the pressure gauge, run the engine at

the lowest possible speed until system pressure builds

to normal levels (minimum 160 psi (11 bar)). Once sys-

tem pressure is established, increase to full operating

speed. If system pressure is not maintained, shut down

the prime mover, determine cause, and take corrective

action.

7.

Operate the hydraulic system for at least fifteen minutes

under light load conditions.

8.

Check and adjust control settings as necessary after

installation.

9.

Shut down the prime mover and remove the pressure

gauge. Replace plug at the charge pressure gauge port.

10.

Check the fluid level in the reservoir; add clean filtered

fluid if necessary. The motor is now ready for operation.

39

40

34

30

41

37

36

33

42

38

35

32

31

(27 Nm)

20 ft.lbs.

5/8 in

(37 Nm)

(37 Nm)

27 ft.lbs.

27 ft.lbs.

11/16 in

11/16 in

30. Orifice Poppet

31. Shift Spool

32. Spring

33. Spring

34. Spring

35. Spring

36. Spring

37. O-ring

38. O-ring

39. O-ring

40. Plug

41. Plug

42. Plug

Figure 3-36. Loop Flushing Spool

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

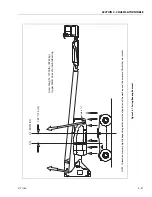

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

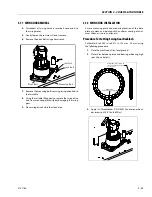

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......