SECTION 3 - CHASSIS & TURNTABLE

3-10

3121160

3.5

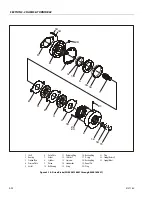

DRIVE HUB (PRIOR TO SN 0300185827)

Disassembly

4.

Position hub over suitable container and remove drain

plugs (10) from unit. Allow oil to completely drain, then

replace drain plugs.

5.

Remove eight bolts (41) and four shoulder bolts (42)

securing cover assembly to hub (7). Remove cover

assembly (23) and discard o-ring seal (22).

6.

Lift carrier assembly and top thrust washer and thrust

bearing (39, 40) from hub. Thrust washer may stick

inside cover.

7.

Pry ring gear (21) loose from hub and remove it. Remove

o-ring seal (22) from hub counter bore and discard it.

8.

Remove input gear (37) and thrust spacer (36) from

input shaft assembly and remove input shaft assembly

from hub.

9.

Lift internal gear (12) and thrust washer and thrust bear-

ing (39, 40) from hub. Thrust washer may stick to bottom

of carrier.

10.

Remove retaining ring (9) from spindle (1) and discard;

lift hub from spindle.

EYE PROTECTION SHOULD BE WORN DURING RETAINING RING REMOVAL.

11.

Remove inside bearing cone (6) and bearing shim (8).

12.

If necessary, pry seal (2) out of hub using screwdriver or

pry bar. With seal removed, outside bearing cone (4) can

be removed.

13.

If necessary, remove inner and outer bearing cones (3, 5)

using a suitable slide hammer puller.

WHEN REBUILDING DRIVE HUB, REMOVE AND REPLACE ALL O-RINGS AND

RETAINING RINGS.

Cleaning and Inspection

1.

Thoroughly clean all parts in an approved cleaning sol-

vent.

2.

Inspect bearing cups and cones for damage, pitting, cor-

rosion, or excessive wear. If necessary, replace bearings

as a complete set ensuring that they remain covered

until use.

3.

Inspect bearing mounting surfaces on spindle, hub,

input shaft and carrier. Replace components as neces-

sary.

4.

Inspect all geared components for chipped or broken

teeth and for excessive or uneven wear patterns.

5.

Inspect carrier for damage, especially in anti-roll pin and

planet shaft hole areas.

6.

Inspect all planet shafts for scoring or other damage.

7.

Inspect all threaded components for damage including

stretching, thread deformation, or twisting.

8.

Inspect seal mounting area in hub for burrs or sharp

edges. Dress applicable surfaces or replace components

as necessary.

9.

Inspect cover for cracks or other damage, and o-ring

sealing area for burrs or sharp edges. Dress applicable

surfaces or replace cover as necessary.

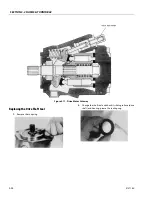

Repair

1.

Cover Assembly.

a.

Remove two bolts (25) securing disconnect cap (26)

to cover (23) and remove cap.

b.

Remove two bolts (25) securing cover cap (24) to

cover and remove cap.

c.

Remove disconnect rod (27) from cap and remove

o-rings (28, 29) from cover cap. Discard o-rings.

d.

If necessary, remove pipe plug (30) from cover.

e.

Clean and inspect parts in accordance with Clean-

ing and inspection procedures. Replace parts as

necessary.

f.

If removed, screw pipe plug into cover.

g.

Slip o-ring (29) over cover cap and against face.

h.

Place o-ring (28) into cover cap internal groove. Dis-

connect rod may be used to push o-ring into

groove.

i.

Place cover cap into cover with large hole located

over pipe plug. Secure cover cap to cover with two

bolts. Torque bolts to 70-80 in. lbs. (7.9-9.0 Nm).

j.

Place disconnect cap over cover cap with nipple fac-

ing out and secure with two bolts. Torque bolts to

70-80 in. lbs. (7.9-9.0 Nm).

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

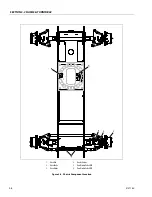

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

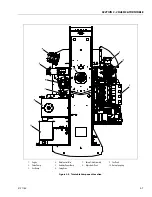

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......