SECTION 3 - CHASSIS & TURNTABLE

3-186

3121160

3.33 GM ENGINE DUAL FUEL SYSTEM

NOTE:

+20° F (-6.6° C) is the low temperature limit for LP gas, for

both starting and operation. This applies to all LP gas pow-

ered engines.

The Dual Fuel system allows the operator to operate the vehi-

cle on either gasoline or LPG by positioning a selector switch

in the operator's platform. When the operator places the selec-

tor switch in the gasoline mode the gasoline fuel pump is

energized. While in the gasoline mode the LPG fuel lock-off is

isolated and will not energize. In addition the gasoline injector

circuit is enabled and injector pulses are provided to each

injector and the ECM calibration for gasoline is also enabled.

When the operator selects the LPG mode the Low Pressure

LPG lock-off is energized and fuel from the LPG tank flows to

the Electronic Pressure Regulator (EPR). The EPR receives an

electronic signal to position the secondary lever for the start or

run positions and when the engine begins to crank the mixer

air valve will rise and fuel will begin flowing to engine. During

this mode the gasoline fuel pump is isolated and will not be

activated. The primary components of the gasoline dual fuel

system are the gasoline tank, electric fuel pump and filter, fuel

supply line, injector rail and injectors and the fuel pressure

regulator. The primary components of the LPG dual fuel sys-

tem are the LPG fuel tank, in-fuel filter, LPG Low Pressure lock-

off, Electronic Pressure Regulator (EPR) and the fuel mixer

module. The LPG fuel system operates at pressures which

range from 14.0 in. (355.60 mm) of water column up to 312 psi

(21.5 bar).

Components which are shared by both systems include the

Electronic Throttle Control and the ECM. The ECM contains a

dual calibration; one controls the gasoline fuel system during

gasoline operation and one controls the LPG fuel system dur-

ing LPG operation.

Fuel Filter

Propane fuel like all other motor fuels is subject to contamina-

tion from outside sources. Refueling of the equipment’s tank

and removal of the tank from the equipment can inadver-

tently introduce dirt and other foreign matter into the fuel sys-

tem. It is therefore necessary to filter the fuel prior to entering

the fuel system components downstream of the tank. An

inline fuel filter has been installed in the fuel system to remove

the dirt and foreign matter from the fuel. The inline filter is

replaceable as a unit only. Maintenance of the filter is critical to

proper operation of the fuel system and should be replaced as

Section 1. In severe operating condition more frequent

replacement of the filter may be necessary.

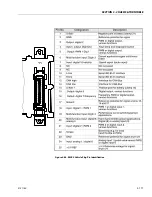

Electric Lock Off

The Electric Lock Off device is an integrated assembly. When

energized the solenoid opens the valve and allows the Pro-

pane fuel to flow through the device. The valve opens during

cranking and run cycles of the engine. The lock off supply volt-

age is controlled by the engine control module (ECM).

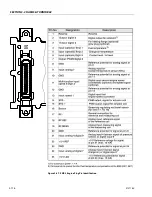

EPR Assembly

The EPR assembly is a combination Low Pressure Regulator

and a Voice Coil Assembly. The Voice coil is an electronic actu-

ator which is controlled by an internal microprocessor. The

microprocessor provides output data to the ECM and receives

input data over a CAN BUS connection. The internal micropro-

cessor receives electrical signals from the Fuel Pressure Sensor

FPS and the Fuel Temperature Pressure FTP and communi-

cates the data to the ECM. The ECM uses the FPS and FTP data

to calculate the location of the secondary lever in the LPR and

sends that data back to the EPR via the CAN BUS. The internal

microprocessor in the EPR will then output a signal, which

causes the voice coil to move and position the secondary lever

to the correct location.

Figure 3-95. Electric Fuel Lock Off

1.

Pressure Regulator Section

2.

Fuel Inlet

3.

Coolant Passage

4.

Primary Test Port

5.

Secondary Test Port

6.

Voice Coil Section

Figure 3-96. EPR Assembly

Содержание 740AJ

Страница 1: ...Service and Maintenance Manual Model 740AJ Prior to S N 0300185827 P N 3121160 October 24 2017 AS NZS...

Страница 2: ......

Страница 51: ...SECTION 2 GENERAL 3121160 2 11 Figure 2 2 Engine Operating Temperature Specifications Ford 4150548 E...

Страница 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Страница 56: ...SECTION 3 CHASSIS TURNTABLE 3 4 3121160 1 Figure 3 2 Axle and Steering Installation Sheet 1 of 2 0258286 C...

Страница 100: ...SECTION 3 CHASSIS TURNTABLE 3 48 3121160 Figure 3 37 Swing Bearing Tolerance Boom Placement Sheet 1 of 2...

Страница 101: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 49 Figure 3 38 Swing Bearing Tolerance Boom Placement Sheet 2 of 2...

Страница 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Страница 124: ...SECTION 3 CHASSIS TURNTABLE 3 72 3121160 Figure 3 45 Swing Drive Hub Fairfield SN 0300074383 through 0300134352...

Страница 180: ...SECTION 3 CHASSIS TURNTABLE 3 128 3121160 1 Figure 3 66 Auxiliary Pump Location 1 AuxiliaryPump 2 HydraulicTank...

Страница 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Страница 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Страница 213: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 161 Megajector Regulator LockoffSolenoid Figure 3 80 LPG System Components Mixer...

Страница 219: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 167 Figure 3 81 Check Out and Initial Start Up Procedures...

Страница 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Страница 225: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 173 Figure 3 84 Deutz EMR 2 Vehicle Side Connection Diagram...

Страница 226: ...SECTION 3 CHASSIS TURNTABLE 3 174 3121160 Figure 3 85 Deutz EMR 2 Engine Side Connection Diagram Sheet 1 of 2...

Страница 227: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 175 Figure 3 86 Deutz EMR 2 Engine Side Connection Diagram Sheet 2 of 2...

Страница 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Страница 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Страница 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Страница 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Страница 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Страница 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Страница 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Страница 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Страница 335: ...SECTION 4 BOOM PLATFORM 3121160 4 63 THIS SENSOR ON NON ADE MACHINES ONLY Figure 4 27 UMS Sensor Location...

Страница 336: ...SECTION 4 BOOM PLATFORM 4 64 3121160 Figure 4 28 UMS Module Location ADE MACHINES NON ADE MACHINES...

Страница 425: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 81 Figure 5 131 Variable Displacement Pump Rexroth...

Страница 443: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 99 Figure 5 146 Fault Logic Troubleshooting...

Страница 444: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 100 3121160 Figure 5 147 Fault Logic Troubleshooting...

Страница 445: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 3121160 5 101 Figure 5 148 Fault Logic Troubleshooting...

Страница 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Страница 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Страница 471: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 11 Figure 6 6 Analyzer Flow Chart Prior to Version 5 X Software Sheet 4 of 4...

Страница 473: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 13 Figure 6 8 Analyzer Flow Chart Version 5 X Software Sheet 2 of 4...

Страница 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Страница 545: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 3121160 7 11 Figure 7 15 Connector Installation...

Страница 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Страница 581: ......