SECTION 5 - BASIC HYDRAULICS INFORMATION & SCHEMATICS

5-24

31215031

NOTE:

Piston and mating end of rod must be free of oil when

installing tapered bushing.

9.

Thread piston on rod until it aligns with spacer.

NOTE:

Apply Medium Strength Threadlocking Compound to new

JLG furnished tapered bushing capscrews when rebuilding

master, slave, lift, and telescope cylinders.

10.

Insert tapered bushing loosely in the piston. Install JLG

capscrews (not vendor capscrews) through drilled holes

in the bushing and tapped holes in piston.

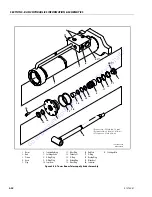

Figure 5-37. Tapered Bushing Installation

11.

Tighten capscrews evenly and progressively, and torque

as shown in Figure 5-28.

12.

Set tapered bushing with a 16-24 oz (454-680g) hammer

and 3/4 in (19mm) brass drift. Place drift against bushing

between capscrews and tap once. Repeat for remaining

two spaces between capscrews.

13.

Re-torque capscrews evenly and progressively, and

torque as shown in Figure 5-28.

14.

Remove cylinder rod from holding fixture.

15.

Position cylinder barrel in a suitable holding fixture.

INSERTING ROD OFF-CENTER CAN DAMAGE PISTON AND CYLINDER BARREL

SURFACES. USE EXTREME CARE WHEN INSTALLING C YLINDER ROD, HEAD,

AND PISTON.

16.

Clamp barrel (1) securely and support rod (2). Insert pis-

ton in cylinder. Do not damage or dislodge piston load-

ing O-ring and seal ring.

17.

Continue pushing rod into cylinder until cylinder head

assembly (3) can be inserted into cylinder.

18.

Align marks made during disassembly.

19.

Apply locking primer (JLG PN 0100038) and Medium

Strength Threadlocking Compound to eight socket

head bolts (9).

20.

Secure cylinder head and washer ring (10) if applicable

with socket head Capscrew (9).

Figure 5-39. Rod Assembly Installation

Rod

Piston

Tapered

Bushing

Rod

Capscrew

Tapered Bushing

3/4in (19mm) Brass Drift

16-24oz (454-680g) Hammer

Figure 5-38. Seating Tapered Bushing

1

2

9

10

3

Go

to

Discount-Equipment.com

to

order

your

parts