SECTION 5 -

SECTION 5 - MAST COMPONENTS

MAST COMPONENTS

3

31

12

21

12

22

28

8

–

–

J

JL

LG

G

L

Liifft

t

–

–

5-9

5-9

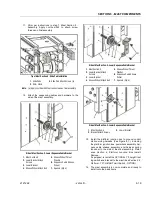

Mast Section-1 - Disassembly

Mast Section-1 - Disassembly

1.

1. Rem

Remove t

ove the fo

he four (4

ur (4) larg

) large scr

e screws (2 e

ews (2 each s

ach side

ide))

attaching the lift cylinder mounting block to mast

attaching the lift cylinder mounting block to mast

section-1. Slide the cylinder out of the mast section

section-1. Slide the cylinder out of the mast section

and move to a suitable work surface.

and move to a suitable work surface.

2.

2. At th

At the top

e top end o

end of mas

f mast sect

t section-1

ion-1, remo

, remove the

ve the pin

pin

attaching the chain anchor block to the mast and

attaching the chain anchor block to the mast and

remove chain/anchor block assemblies from the

remove chain/anchor block assemblies from the

mast and lay aside.

mast and lay aside.

3.

3. Remov

Remove sli

e slide pa

de pads an

ds and shi

d shims f

ms from m

rom mast se

ast section

ction-1,

-1,

if necessary.

if necessary.

Mast disassembly should now be complete.

Mast disassembly should now be complete.

5.

5.9

9 CY

CYLIN

LINDE

DER

R DI

DISA

SASS

SSEM

EMBL

BLY

Y

(See

(See Figure 5-3.

Figure 5-3. )

)

1.

1. Befor

Before dis

e disassemb

assembling

ling the c

the cylind

ylinder

er, clea

, clean away

n away all

all

dirt and foreign substances from openings, particu-

dirt and foreign substances from openings, particu-

larly the head area.

larly the head area.

NOTE:

NOTE:

Always protect the chrome surface of the cylinder

Always protect the chrome surface of the cylinder

rod during assembly and disassembly. Any damage

rod during assembly and disassembly. Any damage

to this surface will require replacement of the rod.

to this surface will require replacement of the rod.

2.

2. Exte

Extend th

nd the rod

e rod until

until the p

the piston

iston bott

bottoms o

oms out ag

ut against

ainst

the cylinder head.

the cylinder head.

3.

3. Comp

Compress t

ress the he

he head ret

ad retraini

raining ri

ng ring en

ng enough

ough to al

to allow

low

the cylinder head to be removed.

the cylinder head to be removed.

4.

4. Caref

Carefully s

ully slide

lide the he

the head/ro

ad/rod/pis

d/piston

ton assemb

assembly o

ly out of

ut of

the cylinder tube. A gentle tap on the head

the cylinder tube. A gentle tap on the head assembly

assembly

may be required to remove the head from the cylin-

may be required to remove the head from the cylin-

der tube.

der tube.

5.

5. Place

Place the

the head/r

head/rod/p

od/piston

iston assemb

assembly o

ly on a

n a surfa

surface

ce

that will not damage the chrome.

that will not damage the chrome.

6.

6. Remov

Remove the

e the pisto

piston loc

n locknut

knut and s

and separa

eparate th

te the pis

e piston

ton

from the rod.

from the rod.

7.

7. Slide

Slide the h

the head o

ead off th

ff the rod

e rod from

from the p

the piston

iston end.

end.

NOTE:

NOTE:

When removing the old seals use only blunt tools, be

When removing the old seals use only blunt tools, be

sure there are no shar

sure there are no sharp edges that may damage the

p edges that may damage the

seal grooves during removal. Scratching the groove

seal grooves during removal. Scratching the groove

may cause by-pass.

may cause by-pass.

8.

8. Rem

Remove

ove and

and dis

discar

card al

d all ol

l old se

d seals

als..

Figure 5-3.

Figure 5-3. Lift Cylinder

Lift Cylinder Component Cross-Section.

Component Cross-Section.

1.

1.

Cylinder

Cylinder Rod

Rod

6.

6.

Apply

Apply Anti-Seize

Anti-Seize

10.

10.

Piston

Piston

2.

2.

Cylinder

Cylinder Head

Head

7.

7.

Cylinde

Cylinder

r Tube

Tube

11.

11.

Wear

Wear Ring

Ring

3.

3.

Rod

Rod Wiper

Wiper

8.

8.

Spacer

Spacer

12.

12.

Piston

Piston O-Ring

O-Ring

4.

4.

Rod

Rod Seal

Seal

9.

9.

Piston

Piston Seal

Seal

13.

13.

Piston Lock

Piston Lock Nut (a)

Nut (a)

5.

5.

O-Ring

O-Ring

Note:

Note: (a) - T

(a) - Torque 100 - 120

orque 100 - 120 ft. lbs.

ft. lbs.

1

1

3

3

4

4

5

5

6

6

8

8

9

9

1

1

2

2

1

1

0

0

1

1

1

1

1

1

3

3

2

2

7

7