6. MISCELLANEOUS

6. MISCELLANEOUS

DRIVING TIPS AND FAULT-FINDING

Problem

Possible cause

Remedy

Uneven stubble or bad cut

The cutter bar is relieved too much.

The number of rpm of the tractor is too

low.

The blades are worn

Discs, stone protectors or flow caps are

deformed.

Check the basic adjustment of the

machine and, if necessary, reduce the

relief by lowering the link arms.

Check that the number of rotations of the

tractor PTO is correct. Keep a constant

number of RPM

Turn/move the blades to another disc or

replace the blades

Replace deformed parts.

Stripes in stubble

The cutting angle is too large, the grass

is not transported across the cutter bar

Accumulation of material in front of the

cutter bar

Earth and grass around the cutter bar

between the discs

You are working early in the morning

when the grass is still very wet

Adjust the cutter bar more horizontal by

lengthening the top link

Increase the driving speed, if possible

Mount flow caps on the discs

Mount special, sharp shearbars or replace

worn shearbars

Increase the driving speed, if possible

Mount flow caps

Irregular flow through the machine

Conditioner fingers may be worn or

missing

The distance between the conditioner

plate and the conditioner rotor is too

long

Replace worn fingers and mount new ones

where these are missing

Adjust the conditioner plate to shorter

distance to the rotor

Increase the driving speed

The machine vibrates/ uneven

operation

Blades may be deformed, damaged or

missing

Defective PTO drive shafts

Defective bearings in cutter bar or

conditioner rotor

Defective flow caps and intensifiers

Earth and grass in flow caps, perhaps

missing foam blocks in flow intensifiers.

Replace or move damaged blades and/or

mount new blades

Check if the shafts are intact. Repair, if

necessary

Check if bearings are loose or damaged.

Replace if necessary

Replace flow caps and intensifiers

Clean flow caps and mount new foam

blocks, if necessary

Gear or cutter bar overheated

Oil level not correct

Check the oil level and refill/drain out oil, if

necessary

NB: Maximum temperature in gearbox 80

degrees, Cutter bar temperature maximum

90-100 degrees

Power consumption unusually high

Crop and dust under the discs

String or wire is wrapped around a

disc.

Stop the tractor engine. Dismount the

discs and clean cutter bar and discs.

Check if the friction clutch is intact.

Remove the foreign matter.

PIGB-093X-06 GX 2402/2802/3202 SM-GX 2402/2802 SC 0410

52

Содержание GX 3202 SM

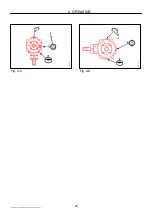

Страница 24: ...3 ADJUSTMENTS AND DRIVING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 24 PR12 0018 Fig 3 10 Fig 3 11...

Страница 26: ...3 ADJUSTMENTS AND DRIVING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 26 Fig 3 12 Fig 3 13 Fig 3 14...

Страница 38: ...4 GREASING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 38 Fig 4 5 Fig 4 6...

Страница 40: ...4 GREASING PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 40 PR11 0045 E Fig 4 7 Fig 4 8...

Страница 44: ...5 MAINTENANCE PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 44 Fig 5 2 PR12 0709 A B D C Fig 5 3...

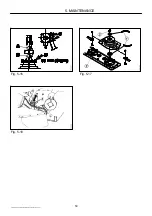

Страница 50: ...5 MAINTENANCE PIGB 093X 06 GX 2402 2802 3202 SM GX 2402 2802 SC 0410 50 Fig 5 16 Fig 5 17 Fig 5 18...

Страница 54: ......