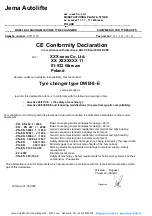

Jema Autolifte A/S Industrihegnet 2 4030 Tune Denmark Tel. (+45) 48180300

www.jemaautolifte.dk

3- bottom position - max backward deflection of column. Subsequent depression of pedal shifts it to

top position 9 moves column to the vertical).

Tyre separator pedal (item.18)

Have two working positions:

1- top position (initial position ) - separator disengaged

2- depressing the pedal engages the separators, release of pedal disengages separator.

Worktable rotation pedal (item.19)

Has three working position:

1- mid position ( initial ) - table drive disengaged

2- pressing the pedal engages clockwise rotation of table (operating rotation), release of pedal

disengages rotation.

3- lifting the pedal with your foot from mid position engages anticlockwise rotation of table 9 emergency

rotation) release of pedal disengages rotation

Slide locking knob (item.20)

Turning the knob from its initial position to the left locks the slide and arm with foot in operating

position. Turning the knob to the left unlocks the slide and throws the arm with foot upwards.

Fig. 5. View of working head

7