safety messages to employer

and safety director

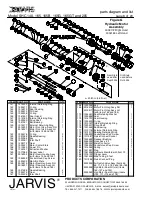

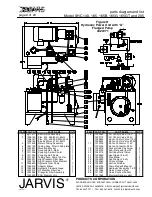

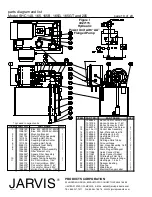

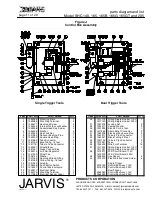

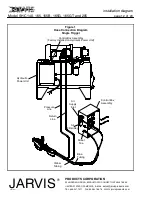

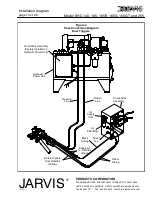

Model SHC 140, 165, 165B, 165G, 165GT and 205

page 2 of 20

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

TEL. 860-347-7271

FAX. 860-347-6978

WWW.

jarvisproducts.com

JARVIS

6207016::::.

1. Ensure

that all employees who use this tool are trained in the proper use of this tool and are aware of

the dangers that may arise if they do not follow the procedures outlined in this brochure.

2. Enclosed

are four (4) copies of “

NOTICE TO OPERATORS, MAINTENANCE AND CLEANUP

PERSONNEL.”

Post one copy on the employees’ bulletin board; give one copy to operator(s); give

one copy to the maintenance foreman; and give one copy to the sub-contract cleanup / internal cleanup

foreman.

Additional copies will be provided upon request.

3.

The tool is designed and intended to be powerful. This fact should be obvious to your employees, but

you must emphasize it to them.

4. Ensure

that employees wear eye protection in accordance with OSHA’s eye and face protection re-

quirements 29 CFR 1910.133 while operating the tool.

5. Ensure

that proper procedures are established in accordance with OSHA’s lockout/tagout procedures

29 CFR 1910.147 to prevent accidental startup or release of stored energy.

6. Remove

and

repair

any tool that malfunctions.

All

personnel must be instructed to remove any

malfunctioning equipment.

7. Never

make modifications or alterations to the tool.

Replace any missing or illegible labels.

8. Follow

our installation and maintenance instructions for proper installation and care of the tool.

9. Avoid

injury. Do not permit the tool to be misused.

10. If

you

resell

or

distribute

a Jarvis product, you must provide the purchaser with the appropriate safety

sheets and tool brochure.

Additional copies of safety sheets and tool brochures will be provided upon

request.

SAFETY MESSAGES TO EMPLOYER AND SAFETY DIRECTOR

AVOID INJURY

Keep hands clear.