installation and

operation instructions

Model SHC 140, 165, 165B, 165G, 165GT and 205

page 15 of 20

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

TEL. 860-347-7271

FAX. 860-347-6978

WWW.

jarvisproducts.com

JARVIS

6207016::::.

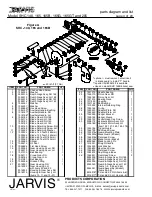

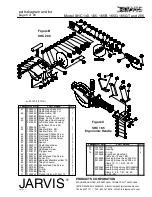

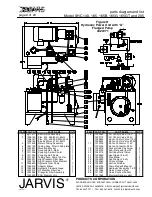

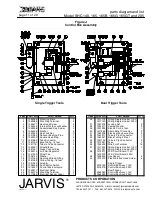

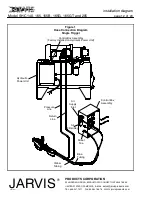

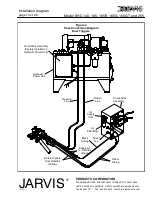

Dual Trigger Tools: Refer to Figure J, page 11.

6.3 For the air supply line: use “Y” fitting (item 124,

Figure F, page 7) to connect black plastic tubing

(item 33) from air filter / regulator (item 15) to

blue plastic tubing (item 122, Figure F, page 7)

from the port marked “IN” on hydraulic man-

ifold (item 187, Figure G, page 8), and to blue

plastic tubing (item 125, Figure F, page 7) from

elbow fitting (item 127, Figure F, page 7) closest

to gear head (item 99, Figure D, page 6).

6.4 For the air return line: use tube to tube connec-

tors (item 34) to connect yellow plastic tubing

(item 19) from tube to pipe connectors (item 34)

to yellow plastic tubing (item 126, Figure F,

page 7) from the port marked “OUT” on hydrau-

lic manifold (item 187, Figure G, page 8), and to

yellow plastic tubing, (item 123, Figure F, page

7) from elbow fitting (item 127, Figure F, page

7) furthest from gear head (item 99, Figure D,

page 6.

For Single and Dual Trigger Tools: Refer to Figure H,

page 9 unless noted otherwise.

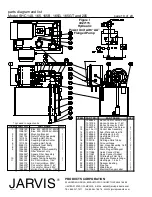

7 Make all necessary hydraulic hose connections.

7.1 Connect the quick connect socket (item 29) of

the supply line marked “A” on the hydraulic

power unit to the quick connect plug (item 190,

Figure G, page 8) connected to the hydraulic

manifold port marked “IN.”

7.2 Connect the quick connect plug (item 28) of the

return line marked “B” on the hydraulic power

unit to the quick connect socket (item 180, Fig-

ure G, page 8) connected to the hydraulic man-

ifold port marked “OUT.”

8 Note: There are no adjustments to be made at the hy-

draulic power unit for blade speed or hydraulic pres-

sure. The blade speed is a result of using the full out-

put of the pump and cannot be increased. The pump

is set to a maximum relief pressure of 2000 psi. Dur-

ing operation, the pressure gage (item 13, Figure H,

page 9) will only show the pressure required to make

the cut. The pressure gage should read approximate-

ly 300 psi with the saw running under no load.

OPERATION INSTRUCTIONS

ALWAYS DISCONNECT ALL HYDRAULIC AND AIR

HOSES AND SHUT OFF THE POWER SUPPLY IN

ACCORDANCE WITH OSHA’S LOCKOUT/TAGOUT

PROCEDURES (29 CFR 1910.147) BEFORE PERFORM-

ING ANY REPAIRS OR MAINTENANCE.

1 Turn on the power.

2

Prior to use or daily,

perform the following tests:

For Single Trigger Tools:

2.1 Make sure that the trigger lever (item 188, Fig-

ure G, page 8) is working correctly. Depress the

trigger and the tool should start. Release the

trigger and the tool should stop.

If the tool mal-

functions, remove it from service and report the

problem to your supervisor immediately

.

Always use two hands when starting and

stopping the tool. Continue holding the tool

with two hands until the saw blade comes to

a complete stop.

For Dual Trigger Tools:

2.2 Make sure that the dual anti--tie down control

triggers on the side and rear handles are working

correctly.

Depress

each trigger separately and

the tool should not start.

Depress

one trigger,

then pause one second and depress the other trig-

ger and the tool should not start. Repeat this pro-

cedure reversing the triggers.

Depress

both trig-

gers simultaneously (within one half second of

each other) and the tool should start. With the

tool running,

release

one trigger and the tool

should stop. Continue holding the depressed

trigger and then depress the other trigger. The

tool should not start.

Repeat

this procedure

holding the other trigger.

If the tool malfunc-

tions, remove it from service and report the

problem to your supervisor immediately

.

Always use two hands when starting and

stopping the tool. Continue holding the tool

with two hands until the saw blade comes to

a complete stop.

2.3 Make sure the SHC saw moves freely on the ba-

lancer.

3 Making the cut.

3.1 Position the SHC saw.

3.2 Depress the trigger fully to start the motor and

make the cut.

Always use two hands when starting the tool

and while making the cut.