07610-001-76-22-N

27

MAINTENANCE

PREVENTATIVE MAINTENANCE

DRIVE GEAR

REDUCER

LUBRICATION

The maintenance procedures detailed here are manufacturer’s instructions for the brand of

gear reducer that is installed on the machines covered in this manual.

LUBRICANTS

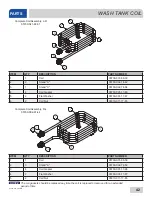

WORM GEAR REDUCERS

For special applications that involve severe ambient

temperature extremes or a seasonal oil requirement,

WINSMITH, based on extensive testing and field

experience, recommends the use of Mobil SHC

synthetic lubricants.

Ambient Temperature

-30 to 15°F

16 to 50°F

51 to 95°F

51 to 95°F

96 to 131°F

96 to 131°F

Final Stage Worm Speed* up to 2000 FPM

up to 2000 FPM

up to 450 FPM

above 450 FPM

up to 450 FPM

above 450 FPM

ISO Viscosity Grade

220

460

680

460

680

460*

AGMA Lubricant No.

5S**

#7 Compounded*** #8 Compounded*** #7 Compounded*** 8 S**

7S**

Mobil

SHC 630

600W Super Cylinder Extra Hecla Super

600W Super Cylinder SHC 636

SHC 634

American Lubricants

SHC-90W

AGMA #7 Gear Oil

AGMA #8 Gear Oil

AGMA #7 Gear Oil

N/A

N/A

Castrol

Tribol 800/220

Tribol 1105-7C

Tribol 1105-8C

Tribol 1105-7C

Tribol 800/680

Tribol 800/460

Chevron

Tegra 220

Cylinder Oil W460

Cylinder Oil W680

Cylinder Oil W460

Tregra 680

Tegra 460

Conoco

Syncon R & O 220

Inca Oil 460

Inca Oil 680

Inca Oil 460

N/A

Syncon R & O 460

Exxon (Esso)

Teresstic SHP 220

Spartan EP 460

Spartan EP 680

Spartan EP 460

Teresstic SHP 680

Teresstic SHP 460

Fiske Brothers

SPO-MG

SPO-277

SPO-288

SPO-277

N/A

N/A

Shell

Omala RL 220

Valvata J 460

Valvata J 680

Valvata J 460

Omala RL 680

Omala RL 460

Texaco

Pinnacle 220

Vanguard 460

Vanguard 680

Vanguard 460

Pinnacle 680

Pinnacle 460

**

*

The sliding velocity in feet per minute (FPM) for standard ratios is determined by multiplying the speed of the worm in RPM by the factor from

the following table. For selecting the proper lubricant, use the speed of the worm in the final stage (input RPM divided by the first stage ratio).

*

**

synthetic oil

***

3% to 10% fatty or synthetic oils or mild EP additives

Lubricant selections are provided by the lubricant manufacturer based on AGMA recommended viscosity grades.

V

iscosity grades are based on Lubrication Standard ANSI/AGMA 9005-D94.

Nominal Ratio

SIZE

4

5

7.5

10

15

20

25

30

40

50

60

80

100

910

—

0.153

—

0.137

0.133

0.122

0.116

0.132

0.121

0.115

—

—

—

913

0.282

0.231

0.189

0.183

0.179

0.171

0.165

0.178

0.169

0.164

0.161

—

—

917

0.402

0.303

0.229

0.201

0.193

0.180

0.172

0.189

0.176

0.170

0.166

0.161

0.133

920

0.311

0.347

0.263

0.225

0.216

0.202

0.191

0.215

0.200

0.188

0.182

0.164

0.161

924

0.388

0.412

0.312

0.261

0.256

0.236

0.223

0.249

0.231

0.216

0.210

0.201

0.196

926

0.529

0.455

0.345

0.283

0.276

0.254

0.238

0.269

0.249

0.234

0.225

0.215

0.210

930

0.582

0.520

0.395

0.327

0.317

0.291

0.273

0.307

0.285

0.269

0.258

0.246

0.241

935

0.656

0.607

0.461

0.427

0.412

0.373

0.349

0.403

0.367

0.345

0.330

0.311

0.299

943

0.710

0.633

0.588

0.568

0.553

0.507

0.558

0.544

0.501

0.475

0.457

0.435

0.422

20

*The sliding velocity in feet per minute (FPM) for standard ratios is determined by

multiplying the speed of the worm in RPM by the factor from the following table. For

selecting the proper lubricant, use the speed of the worm in the final stage (input RPM

divided by the first stage ratio).

**Synthetic oil.

***3% to 10% fatty or synthetic oils or mild EP additives.

Lubricant selections are provided by the lubricant manufacturer based on AGMA

recommended viscosity grades.

Viscosity grades are based on Lubrication Standard ANSI/AGMA 9005-D94.

Factory filling

- Speed reducers are filled with oil at the factory to the proper level for

the standard mounting position it will be found on the machine. The oil level should be

checked and adjusted (if necessary) before operation, using the oil level plug provided and

while the machine is oriented in its operating position.

Ambient temperature

- If the operating ambient temperature is other than 51 - 95 °F,

refer to the lubrication chart and refill the

machine with the correct grade based on actual

ambient temperature and operating speed. See “Oil changing” below for additional

information.

Oil changing

- When changing the oil for any reason, it should be remembered that oils

of various types might not be compatible. Therefore, when changing to a different oil, it is

recommended that the housing be completely drained and thoroughly flushed with a light

flushing oil before refilling with the appropriate lubricant. The oil level should be rechecked

Size

5

7.5

10

15

20

25

30

40

50

60

80

100

920

0.347

0.263

0.225

0.216

0.202

0.191

0.215

0.200

0.188

0.182

0.164

0.161

Nominal Ratio

Содержание AJ-44

Страница 72: ...64 07610 001 76 22 N PARTS AJ 66 RACK RAILS Left to Right Right to Left 1 4 2 3 4 5 6 7 1 ...

Страница 84: ...76 07610 001 76 22 N SCHEMATICS AJ 44CGP 208 230 V 60 HZ 1 PHASE AJ 44CGP SCHEMATIC ...

Страница 85: ...07610 001 76 22 N 77 SCHEMATICS AJ 44CGP 208 230 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Страница 86: ...78 07610 001 76 22 N SCHEMATICS AJ 44CGP 460 V 60 HZ 3 PHASE AJ 44CGP SCHEMATIC ...

Страница 87: ...07610 001 76 22 N 79 SCHEMATICS AJ 66CGP 208 230 V 60 HZ 1 PHASE AJ 66CGP SCHEMATIC ...

Страница 88: ...80 07610 001 76 22 N SCHEMATICS AJ 66CGP 208 230 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...

Страница 89: ...07610 001 76 22 N 81 SCHEMATICS AJ 66CGP 380 460 600 V 60 HZ 3 PHASE AJ 66CGP SCHEMATIC ...

Страница 91: ...07610 001 76 22 N 83 SCHEMATICS SIDE LOADER ...