M

AINTENANCE

8.6.3. Re-lubricate the lifting motor

CAUTION

Danger of injury from pre-tensioned

springs

Pre-tensioned springs are released when disas-

sembling the engine covers.

I

Carefully loosen and remove the engine cover!

NOTICE

The grease filling in the rotor chambers is suffi-

cient for approximately 250hours under normal

operating conditions. The rotor chambers only

empty to approximately 75%. In this condition,

refilling must be performed.

NOTICE

See the spare parts list for tightening torques

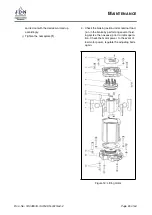

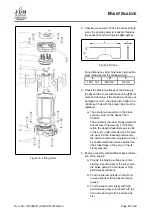

In order to re-lubricate the motor, it must be re-

moved (Abbildung (

,

→

Figure 13, the lifting motor

can be removed from the hoist to simplify matters):

1. Engine disassembly:

a) Relieve the product and disconnect from

the power supply.

b) Unscrew the nameplate

(1)

.

c) Remove the motor cover bolts

(2)

and

detach the engine cover

(3)

(when the

cover bolts are loosened, the tension in

the brake springs

(4)

is fully released).

d) Remove the brake springs.

e) Remove the brake piston

(5)

from the

internal cylinder integrated in the engine

housing. If present, bore holes can be

used to facilitate assembly.

f) Pull out the rotor

(6)

htogether with

vanes

(7)

and starting aids

(8)

.

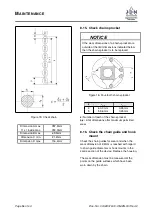

2. Renewing motor lubrication:

The retaining rings

(9)

and Vyon washers

(10)

must be removed in order to refill the lubrica-

tion chambers of the rotor. Then fill the lubri-

cant chambers with high-performance lubri-

cant (JDN item. no 11904) without forming

cavities! Use new Vyon washers to close off

the lubricant chambers and secure these us-

ing retaining rings.

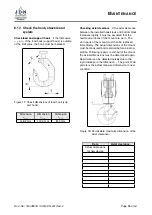

3. Engine assembly with additional basic lubrica-

tion of the engine:

a) Provide the braking surface and rotor

bearing (needle bush) of the cover with

the brake pad with a thin layer of high-

performance lubricant.

b) Coat the internal cylinder of the motor

housing lightly with high-performance

grease

c) Coat the entire rotor lightly with high-

performance grease and insert into the

front rotor bearing with the clutch side

first.

d) Coat the vanes lightly with high-

performance grease and insert into the

rotor slots with the starting aids.

e) Coat the entire braking piston surface, in-

cluding the brake piston seal, lightly with

high-performance lubricant and push

the brake piston into the internal cylinder

with the braking surface first. Note the

position of the eccentric bore.

f) Insert the brake springs into the bores of

the brake piston.

g) Loosen adjustment bolts

(14)

and lock

nuts

(15)

. Screw back adjusting bolts

sufficiently.

h) Apply high-performance grease lightly to

rotor bearing (needle bush) in the mo-

tor cover and install motor cover. Ensure

correct seating of the brake springs and

the locating pins to the motor housing

and to the brake piston. Do not tighten

the four adjusting bolts after bolting the

motor cover in place, only screw them in

loosely by hand to the stop in the cover.

Screw back the lock nuts sufficiently be-

forehand.

i) Then screw back the adjusting bolts

45

◦

from the stop, hold and lock with

the nuts. For lifting heights of 10 metres

(33 feet) and more, a setting of up to 60

◦

may be required. For operation in areas

with ambient temperatures exceeding

30

◦

C (86

◦

F), the adjustment must be

Page

48

of 64

Doc.-No.: VA049318-10-OM-EN-0319-64-2