installation directiVe

68

MAY 2006

N40 ENT M25

N60 ENT M37-M40

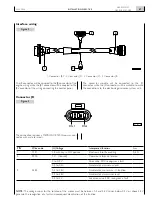

Figure 4

If required, a second model of the oil filter support is available.

This enables the replacement of the filers when the motor

is rotating. During replacement, cartridges are alternatively

excluded from the lubrication system in order to guarantee

the continuity of the filtering action through the cartridge

which is kept in the circuit (see figure 4). The replacement

method is described in the “use and maintenance” manual.

1. Connecting element - 2. Commutation lever -

3. Lubricating oil filters.

For the cases where it is required to position the filter in a

more accessible place, a connecting element is available. This

enables the bypassing of the filter in coming pipes (see figure

5). In order to guarantee that the correct pressure value is

maintained in the lubrication system during the installing of

remote filters, do as follows:

CAUTION

the filter must be installed in a vertical position.

the point where the filter is screwed to the support

should always be under the connecting point of the adap-

tor on the engine.

o

For a correct preparation, draw a line from the adaptor

connecting point. The angle between this line and the

horizontal surface must be equal to the maximum incli-

nation which the boat can reach on the longitudinal and

transversal axis. The screwing point must be positioned

under this line (see figure n. 5).

REMOTE OIL FILTERS

1

2

3

Figure 5

05_002_N

05_003_N

Prescriptions

o

Pipes must be adapted to the temperature and pressure

conditions typical of the engine model.

o

The pressure fall in each pipe, including its connection,

must be lower than 0,05 bar at 20°C under maximum

range conditions.

o

The pipes must not touch engine parts and they must

be fixed at least in two intermediate points between the

ends. The lengths of each pipe must not be more than

1200 mm.

o

Tubes must be flexible.

Содержание NEF N40-ENT-M25

Страница 64: ...INSTALLATIONDIRECTIVE 64 N40 ENT M25 N60 ENT M37 M40 MAY 2006 ...

Страница 69: ......