installation directiVe

42

MAY 2006

N40 ENT M25

N60 ENT M37-M40

17. PREPARING THE ENGINE

FOR FIRST START-UP

1. Drain the residual 30/M protective oil from the sump.

2. Pour into the lubricating loop only lubricating oil of the

type and in the quantities set out in the Refilling Table.

3. Drain the CFB protective liquid from the fuel loop,

completing the operations as indicated under item 3. of

Chapter 23.

4. Remove the caps and/or seals from the engine intake,

exhaust, aeration and venting ports, restoring normal

conditions of use. Connect the inlet of the turbocharger

to the air filter.

5. Connect the fuel loops to the boat tank, completing

the operations set out in item 4. of Chapter 23. During

filling operations, connect the pipe returning fuel to the

tank to a collecting container, to prevent residues of CFB

protective liquid from ending up into the boat tank.

6. Verify and refill engine coolant as prescribed.

7. Remove from the engine the labels with the inscription

“ENGINE WITHOUT OIL”.

Although they are extremely important, “common sense”

checks such as the exposure of sensitive parts (plastics, wire

harness, electronic units, etc...) to heat, and those that for

years have characterized the quality of the work performed

in the yard, are not mentioned herein.

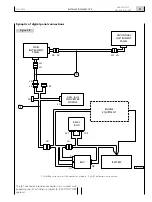

Tests of the proper operation of the engine and the com-

ponents of the electronic control system may be performed

rapidly and with the utmost reliability using specific diagnostic

tools, available from IVECO MOTORS Technical Assistance

Centers.

Fuel tank suction

Verify the fuel suction at the maximum allowed longitudinal

and transverse inclination, with the residual quantity of fuel

considered “RESERVE”, such as to cause the reserve indica-

tor light to be permanently lighted.

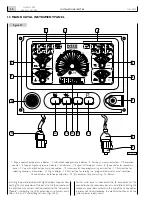

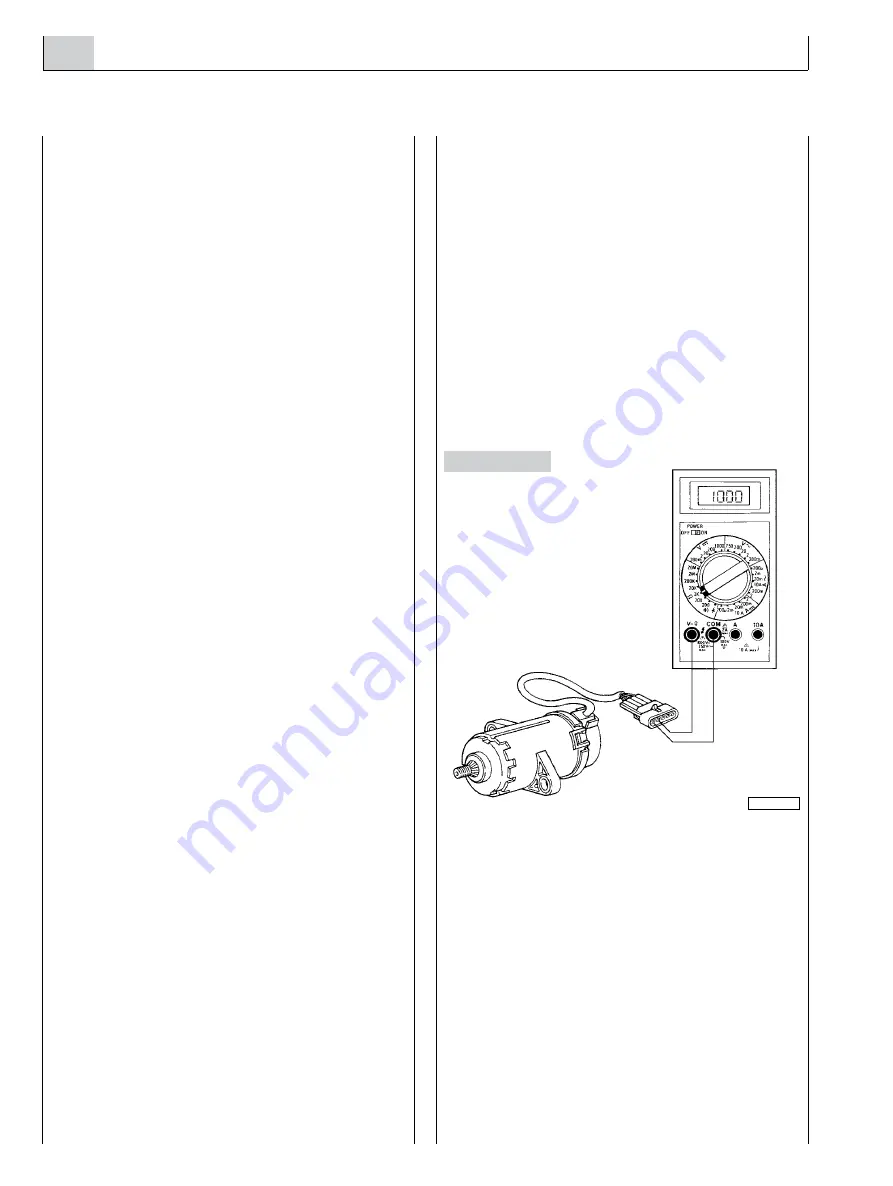

Throttle lever position sensor

In the positions of minimum and maximum travel, verify the

correlation between the position of the throttle control valve

on the bridge and the position of the sensor rod, checking:

o

That in the resting position the safety switch inside it is

electrically open. Carry out the test with an ohmmeter

between the points D and E of the potentiometer

connector.

- Value read

∞

Ω

= optimal adjustment;

- Value read 1 k

Ω

= a better mechanical adjustment of

the resting position is required, to bring the value back

to

∞

Ω

.

o

In the position of maximum acceleration, the rod of the

sensor has reached the mechanical end stop.

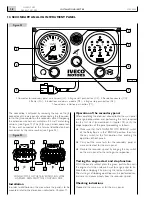

Instrument panel

Verify the efficiency of all light indicators, as described in the

related Chapters.

04_080_N

Figure 42

18. TESTS BEFORE

THE FIRST START-UP

Содержание NEF N40-ENT-M25

Страница 64: ...INSTALLATIONDIRECTIVE 64 N40 ENT M25 N60 ENT M37 M40 MAY 2006 ...

Страница 69: ......