If other types of couplings are used, then follow the maintenance instructions provided by the coupling

manufacturer.

6.4 Shaft-seal maintenance

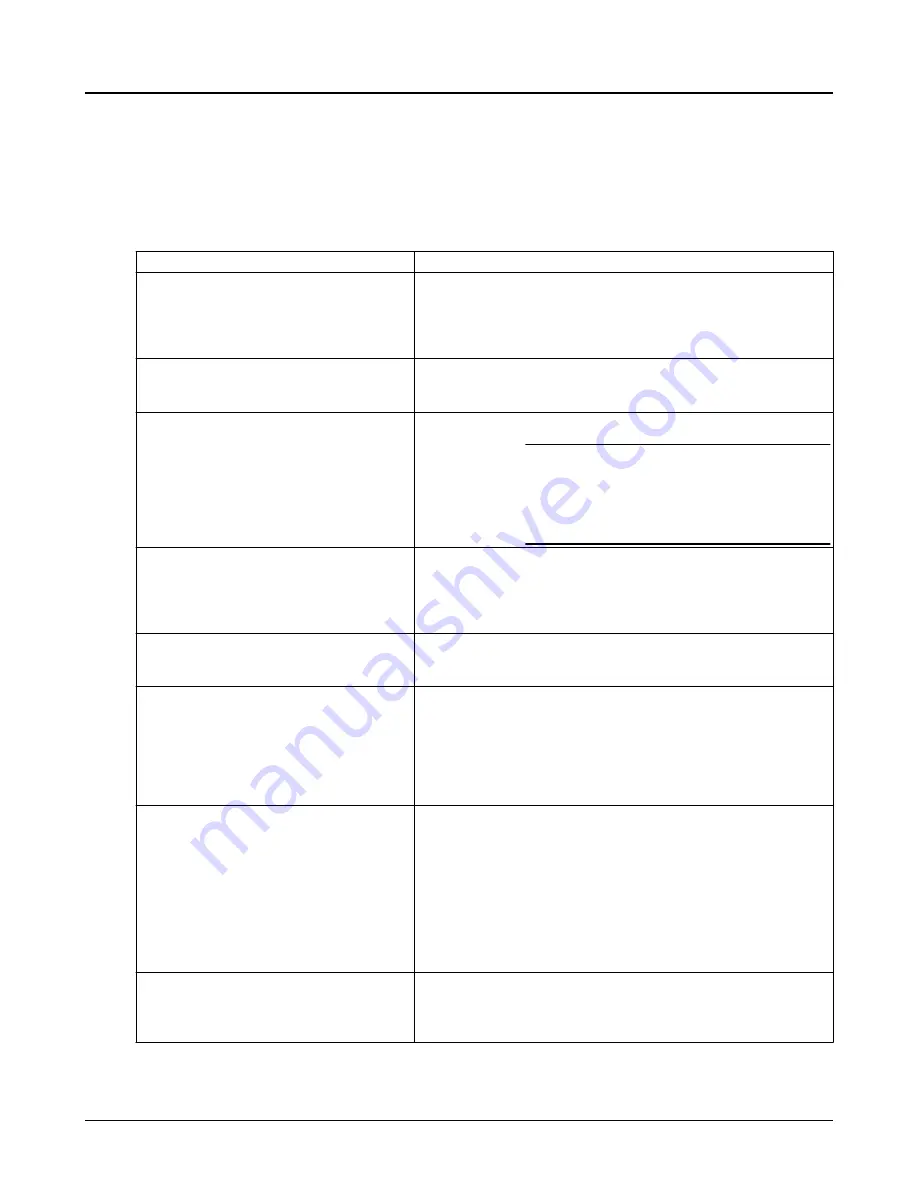

6.4.1 Packed stuffing box maintenance

Check or instruction

Explanation/comment

When starting a pump with fiber packing for

the first time, make sure that the packing is

slightly loose without causing an air leak. As

the pump runs in, gradually tighten the gland

bolts evenly.

Never draw the gland to the point where the packing is compressed

too tightly and no leakage occurs. This will burn the packing, score

the shaft sleeve, and prevent circulation of the liquid that cools the

packing.

Turn the rotating element by hand.

The stuffing box is improperly packed or adjusted if friction in the box

prevents turning the rotating element by hand. A properly operated

stuffing box runs lukewarm with a slow drip of sealing liquid.

After the pump has been in operation for

some time and the packing is completely run

in, check that the stuffing box leaks at the

rate of 40–60 drops per minute.

This indicates proper packing, shaft sleeve lubrication, and cooling.

NOTICE:

Eccentricity of the shaft or sleeve through the

packing can result in excess leakage. Make sure

that the parts are properly centered.

Check the packing frequently and replace as

service indicates.

Six months is a reasonable expected life, depending on operating

conditions. Use a packing tool in order to remove all old packing from

the stuffing box. Never reuse old packing or add new rings to old

packing. Clean the stuffing box thoroughly before you install new

packing.

Check the condition of the shaft or sleeve for

possible scoring or eccentricity and make re-

placements as necessary.

—

When placing new, non-asbestos packing in-

to the stuffing box, open the molded rings

sideways and push the joints into the stuffing

box first. Then install the rings one at a time,

making sure to seat each ring firmly. Stagger

the joints at a 90° rotation from each preced-

ing joint.

—

If coil packing is used, then cut one ring to

the accurate size with either a butt or mitered

joint. Fit the ring over the shaft to assure the

proper length, and then remove and cut all

the rings to this first sample. When you place

the rings around the shaft, make sure to form

a tight joint. Place the first ring in the bottom

of the stuffing box. Then install each suc-

ceeding ring. Stagger the joints at a 90° rota-

tion.

An accurately cut butt joint is superior to a poorly fitted mitered joint.

Make sure that each ring is firmly seated.

If a seal cage is supplied, check that it is

properly located in the stuffing box under the

sealing water inlet.

The function of the seal cage is to establish a liquid seal around the

shaft, to prevent leakage of air through the stuffing box, and to lubri-

cate the packing. If it is not properly located, then it serves no pur-

pose.

6.4 Shaft-seal maintenance

42

Model 3409 Installation, Operation, and Maintenance Manual

Содержание Goulds Pumps 3409

Страница 1: ...Installation Operation and Maintenance Manual Model 3409 ...

Страница 2: ......