Easy Start Guide

Page 13

This guide has been produced by The Inverter Drive Supermarket Ltd.

All content, including but not limited to graphics, text and procedures copyright

The Inverter

Drive Supermarket and must not be reproduced or altered without prior written permission.

©

13. How to configure “3-Wire” control with Run/Stop

pushbuttons and Forward/Reverse selection

The parameters described in Section 5 enable

Run/Stop operation via the red and green

buttons on the Inverter.

If this is unsuitable for the application, remote

switches can be used instead.

This section explains how to enable 3-wire

control with Run and Stop via pushbuttons and

Forward/Reverse via a selector switch.

Ensure the Inverter is in “Remote” mode

before continuing.

Parameter

Description

How to set

P000

Parameter Access

Set to

to allow parameters to be changed

5

P230

Remote Command Selection

Set to

to use the Inverter terminals (as opposed to keypad)

1

P263

Digital input 1 (T1) function

Set to

for 3-wire control “Start” on T1 (ignore E24 error, will clear when P264 is set)

14

P264

Digital input 2 (T2) function

Set to

for 3-wire control “Stop” on T2

14

P265

Digital input 3 (T3) function

Set to 1 for reset on T3 (or set to 1, 3, 6, 11, 12, 13 or 15 as required but no other values)

0

P266

Digital input 4 (T4) function

Set to

for forward/reverse selection on T4

0

13.1 Parameters to change for remote 3-wire control

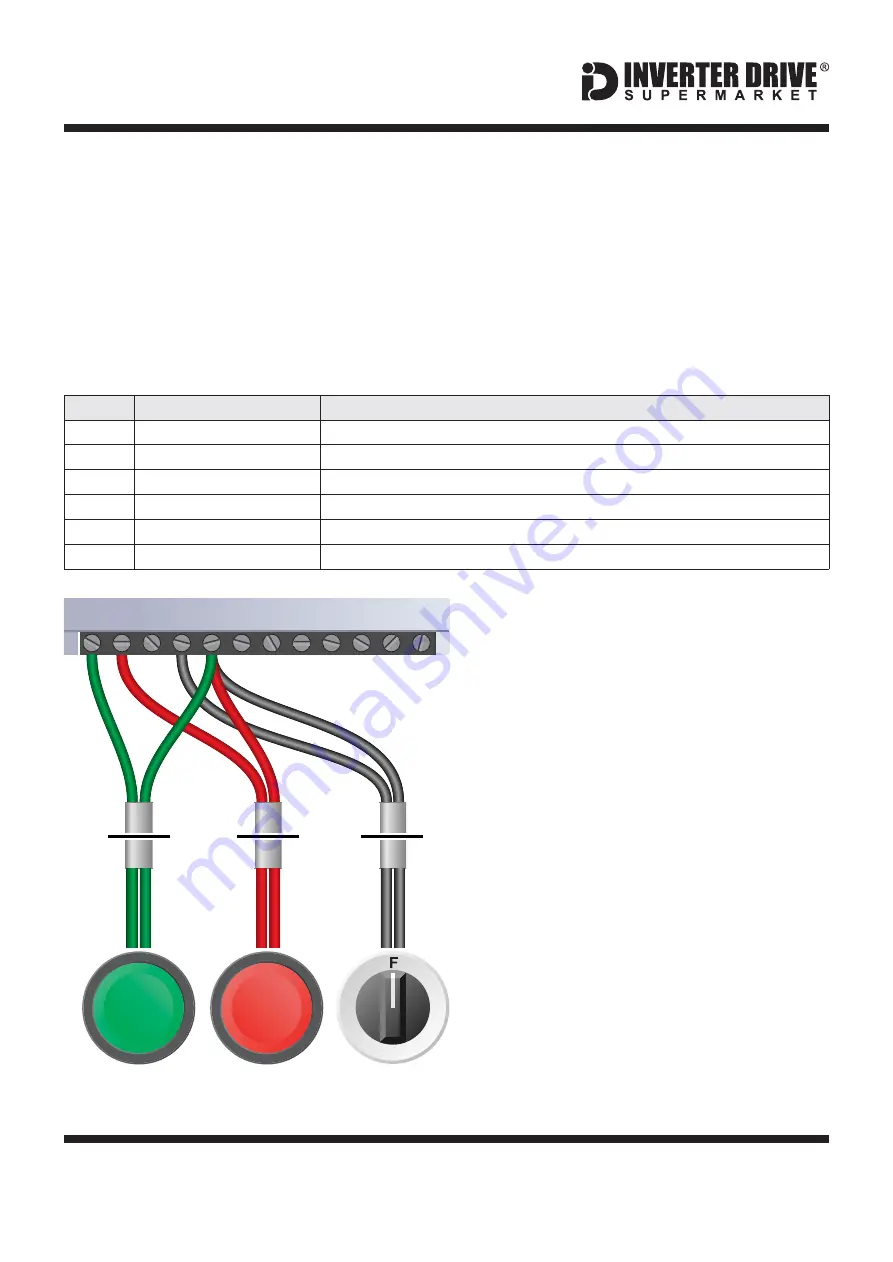

13.2 Connecting the Switches

A wiring diagram is shown in the illustration

opposite.

For “Run” and “Stop”, two suitable

pushbuttons should be installed. The “Run”

pushbutton should include a Normally Open

contact between terminals 5 (COM) and 1

(DI1) and the “Stop” a Normally Closed contact

between terminals 5 (COM) and 2 (DI2).

For “Forward/Reverse” a suitable 2 position

NO (

) switch should be installed

between terminals 5 (COM) and 4 (DI4).

A momentary connection between 5 (COM)

and 1 (DI1) will start the motor. It will continue

to run until the connection between 5 (COM)

and 2 (DI2) is broken.

Terminal 5 (COM) is a common

connection for terminals 1-4, 6 and 8 and has

no other function.

Normally Open

Note that the Forward/Reverse switch only

selects the direction of rotation - it will not start

or stop the motor. If the application only

requires the motor to turn in one direction, the

Forward/Reverse switch can be omitted.

1

2

1

4

Pushbutton

Normally Open

“Run”

R

Pushbutton

Normally Closed

“Stop”

Switch, 2 Position

Normally Open

“Forward / Reverse”

1

3

WEG CFW-08 Series Inverter

1 2 3 4 5 6 7 8 9 10 11 12

COM

DI1 DI2

DI4

1

4

3

2