41

R05

S

CHEDULE

O

F

P

REVENTIVE

M

AINTENANCE

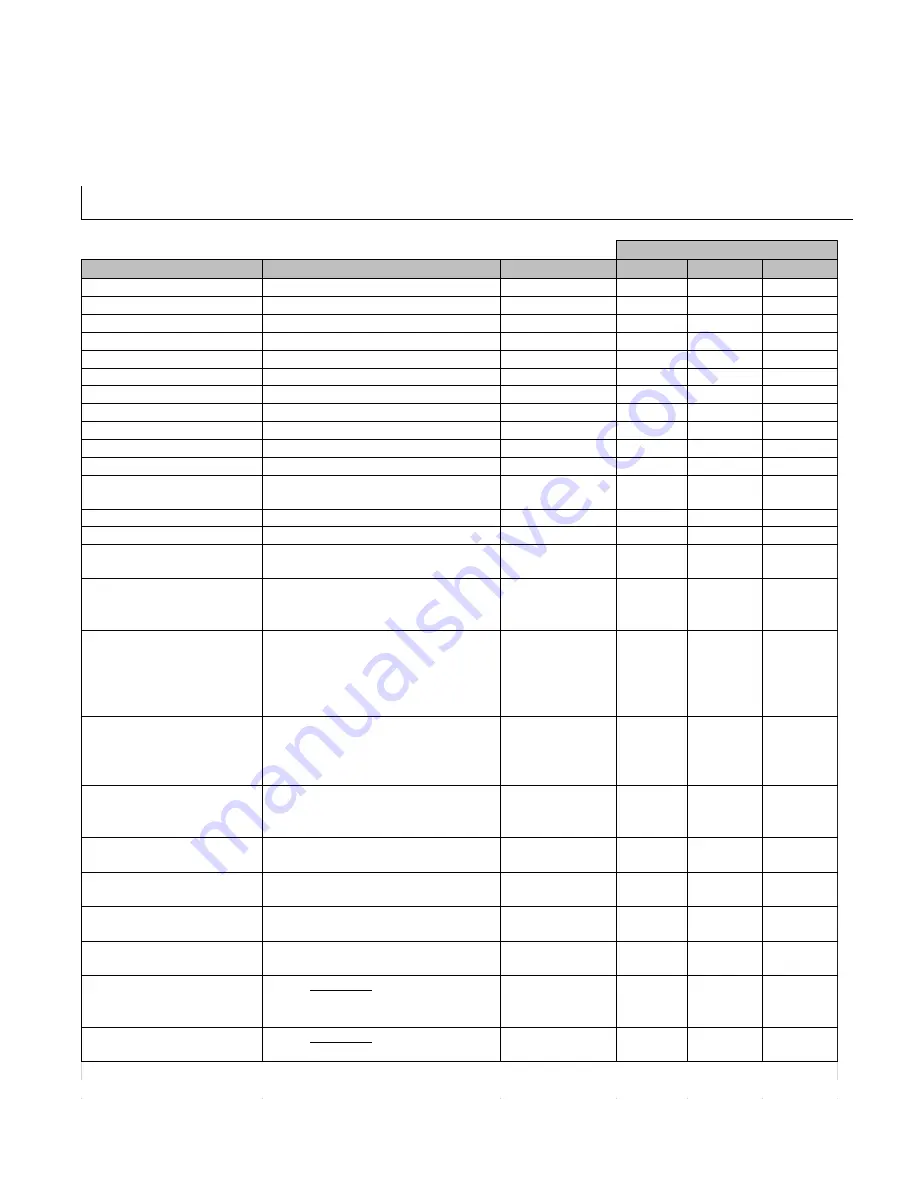

Item

Action Required

Material

Weekly

Monthly

Quarterly

Blade Guard Oiler Pad

Lubricate

Lightweight oil

X

Hardware

Re-tighten any loose hardware

X

Replace any missing hardware

X

Cutter Blade

Inspect for wear

X

Clean

Solvent Cleaner

X

Mandrel Assembly

Disassemble & Observe

X

Mandrel Friction Washer Clean

Solvent Cleaner

X

Mandrel Metal Washer None

None

X

Mandrel Shaft Remove any dust and adhesive build up

Solvent Cleaner

X

Mandrel Bearing Check for wear

None

X

Peel Roller

X

Delrin Roller Check for free spinning. Disassemble and

remove any adhesive build up.

Solvent Cleaner

X

Pivot Shaft Check for any restriction

Solvent Cleaner

X

Peel Roller Spring Check for total extension when force.

X

Plastic Guide Rollers

Check for free spinning. Disassemble and

remove any adhesive build up.

Solvent Cleaner

X

Knurled PTFE Coated Direction

Clutch Roller

Back off tension. Check for free spinning.

Disassemble and remove any adhesive build

up. Oil needle rollers.

Solvent Cleaner

X

Knurled PTFE Guide Rollers

Rotation should be slightly restricted by

spring. Disassemble and remove any

adhesive build up if excessive restriction is

detected. Check one way bearing grease

bearing.

Oiled string and

Damp Cloth

X

Front Blue Wipe Down Roller

Rotation should be slightly restricted by

spring washer. Disassemble and remove any

adhesive build up if excessive restriction is

detected.

Solvent Cleaner

X

Rear Blue Wipe Down Roller

Check for free spinning. Disassemble and

remove any adhesive build up. Check swivel

bushing.

Solvent Cleaner

X

Main Spring

Remove and inspect for any wear or

weakness. Replace as necessary.

X

Knife Spring

Remove and inspect for any wear or

weakness. Replace as necessary.

X

Tape Shoe Guide Compression

Spring

Inspect for finger popping up. Replace as

necessary.

X

Wipe Down Tab

Inspect for any wear or weakness. Replace

as necessary.

X

Main Applying And Wipe Down

Assembly

Remove

Main Spring

and check for any

restrictions when assembly is in motion

Worn bearings, bent

shafts, bent roller

arms

X

Knife Arm Assembly

Remove

Knife Spring

and check for any

restrictions when assembly is in motion

Worn bearings, bent

shafts.

X

Frequency

Refer To Assembly Drawings For Part Numbers Of Replacement Parts If Required

Содержание ET xtreme Series

Страница 1: ...1 R05 ET xtreme STANDARD TAPE HEAD Serial Numbers UH230T UH430T ...

Страница 2: ...2 R05 ...

Страница 10: ...10 R05 SPECIFICATIONS UUUTape Head Dimensions Figure 6 1 ...

Страница 11: ...11 R05 SPECIFICATIONS UUU Tape Head Components Figure 6 2 ...

Страница 43: ...43 R05 THIS PAGE INTENTIONALLY LEFT BLANK ...

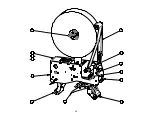

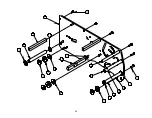

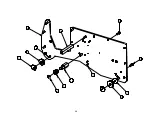

Страница 44: ...4 6 10 8 1 9 3 5 7 2 11 12 13 44 ...

Страница 46: ...1 15 2 3 6 10 12 14 7 11 8 9 5 4 16 14 13 13 4 18 17 46 ...

Страница 48: ...6 11 8 14 2 12 9 7 10 5 3 3 13 48 ...

Страница 50: ...6 7 15 11 10 14 4 2 9 3 5 13 12 8 1 16 50 ...

Страница 52: ... 8 8 ...

Страница 53: ... 7 0 3 57 6 5 37 21 8 47 8 47 83 8 52 5 83 2035 66 21 635 1 83 8 52 5 ...

Страница 54: ...2 4 1 5 3 54 ...

Страница 56: ... 8 8 ...

Страница 58: ... 86 86 ...

Страница 60: ...2 4 1 3 5 6 5 60 ...

Страница 62: ...2 3 6 5 1 8 4 12 9 7 9 10 11 62 ...

Страница 64: ...5 15 7 6 12 2 14 4 3 13 10 8 9 1 11 16 64 ...

Страница 66: ...3 1 2 2 1 3 Standard Tape Head Mirror Tape Head 66 ...

Страница 68: ...5 2 10 4 11 3 8 6 7 1 9 12 68 ...

Страница 70: ...1 3 2 70 ...

Страница 72: ... 8 8 ...

Страница 74: ...6 1 2 5 3 4 74 ...

Страница 76: ...19 4 9 16 6 7 5 8 1 11 3 10 14 12 15 13 18 17 2 20 76 ...

Страница 78: ...1 2 No Tape options are available 78 ...

Страница 79: ...ITEM PART DESCRIPTION QTY 1 UPM7328 PHOTOELECTRIC SENSOR PNP 1 2 UPM7329 PHOTOELECTRIC SENSOR NPN 1 79 ...

Страница 80: ...1 2 3 Low Tape options are available 80 ...