Page 12

EN

Chapter 4 Assembly and function

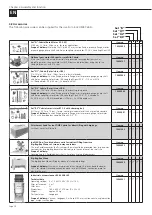

3.11 Rotor/Stator

Depending on the set select-

ed or area of application

Set “D”: D7-2.5S

Set "Ü1: 1R6

Set “Ü2”: 2R6

Set “RS”: R7 - 1.5

with clamping

strip

3.12 Noise emission

Sound power level LWA

78 dB (A)

3.13 Operating conditions

Temperature range

2 - 45 °C

Relative humidity, maximum

80 %

4 Assembly and function

4.1 Scope of delivery inoCOMB Cabrio

Item no. 10042612

Small silo consisting of:

• Frame

• Material container

• Switching cabinet

• Vibrating unit

Mixing unit consisting of:

• Gear motor 373 rpm

• Water fitting

• PU mixing tube inoPower Mix “S” with wide material

outlet

Pump unit consisting of:

• Extendable feed pump

• Stainless steel pump housing

• Gear motor frequency controlled

• Toolbox

Set “D” Cabrio

for spray applications (22 l / 40 bar)

Item no. 10043990*

Set “Ü1” Cabrio

for industrial screeds (100 l / 15 bar)

Item no. 10043988*

Set “Ü2” Cabrio

for floor levelling compounds (100 l / 30 bar)

Item no. 10043989*

Set “RS” Cabrio

for coarse-grained material (50 l / 15 bar)

Item no. 10043991*

_____________________________

* For scope of delivery, see accessories

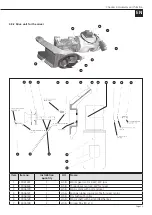

4.2 Functionality

The small silo inoCOMB Cabrio is used for mixing and con-

veying pumpable (mineral or organic products) materials up

to approx. 8 mm grain size. Dry mortar, screed material or

floor levelling compounds pre-mixed by the material manu-

facturer can be used. The material hopper of the small silo

can optionally be filled with bagged material, with one-way

containers or with big bags. During operation, the dry ma-

terial is conveyed from the material hopper into the mixing

pipe via the metering shaft. In the mixing tube, the dry ma-

terial − with the addition of water − is mixed with the mix-

ing shaft to form a homogeneous, pasty or liquid product.

At the outer end of the mixing tube, the mixed material falls

directly into the pump hopper. In the pump hopper, the ma-

terial is transported to the pump unit (rotor/stator) via the

pump shaft. The material is pumped from there via the ma-

terial hoses to the processing location. There, it is applied to

walls and ceilings with appropriate spray/adhesive guns or a

reprofiling sprayer or poured directly onto the floor.