TNi21

07 April 2016

Page

14/38

4.1. Snapshot of the installation procedure

The installation procedure is described in the follow sections:

Electromagnetic compatibility, EMC

Before fitting

Fitting the motor

Electrical installation

Check that these sections have been read and understood and that, subsequently, the motor has been

installed correctly.

4.2. Electromagnetic compatibility, EMC

DANGER

INTERFERENCE AFFECTING SIGNALS AND EQUIPMENT

Interference with signals can cause equipment to behave

unpredictably

• Wiring should be done in accordance with the EMC

recommendations specific to each device.

• Ensure that these EMC recommendations are followed correctly.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

Recommendations with regard to EMC: installing the motor's power supply wiring.

At the wiring planning stage, consider that the motor's power supply wiring must be installed isolated from

network or signal transmission cables.

Take the following measures with regard to EMC.

EMC measures

Effect

Keep cables as short as possible.

Do not install loops of unused cable.

Reduce interference, capacitive and inductive

couplings.

Earth the product.

Reduce emissions; increase immunity to

interference,

Where shielded cables are used, the cable

shielding should be fitted to the widest possible

surface area. Use cable clamps and earth bands.

Reduce emissions.

Position the motor's power supply wires separate

from cables that carry signals or use screening

plates.

Reduce mutual interference

If screened cables are used, fit them without an

isolation point.

1)

Reduce radiating interference.

1) Where the installation requires a cable to be cut, cables must be connected at the isolation point via a shielded cable inside a

metal enclosure.

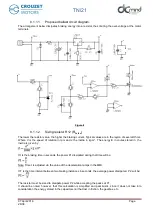

Equipotential link conductors

Where screened cables are used, differences in voltage can cause currents not permitted in screened

cables. Fit equipotential link conductors to reduce current in screened cables.