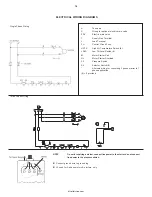

The basic principle of operation is as follows: On the suction stroke

of the first-stage piston(s), air at atmospheric pressure enters the

cylinders through the inlet filter(s) and then the inlet valves located

in the head. On the compression stroke of the first-stage piston(s),

the air is compressed to an intermediate pressure and discharged

through the discharge valves(s) into common manifold(s). From the

manifold(s) the air passes through the intercooler tubes, where the

heat of first-stage compression is removed. On the suction stroke of

the second-stage piston this cooled air enters the second-stage

cylinder through the inlet valve. The compression stroke of the

second-stage piston compresses the air to the final discharge

pressure and forces it out through the discharge valve into the

receiver tank or system. If cooling of the discharge air is required,

an air-cooled aftercooler should be installed between the

compressor discharge and the receiver tank or system.

For maintaining the receiver tank or system air pressure within

predetermined limits, the compressor may be operated with

automatic start & stop control or constant speed control regulation.

The type of regulation used depends upon the application.

ADDITIONAL REFERENCES ___________________________

Unless otherwise stated, dimensions, weights and measurements

are provided in standard U.S. measure followed in parentheses by

the metric conversion. Any torque values given are stated in inch or

foot pounds followed by the Newton-meter equivalent in

parentheses. Electrical characteristics are given in

voltage-phase-hertz.

RECEIPT & INSPECTION

Ensure adequate lifting equipment is available for unloading and

moving the unit to the installation site.

NOTE

Lifting equipment must be properly rated for the

weight of the unit.

•

CAUTION

Lift the unit by the shipping skid only. Do not use

the motor lifting eye to lift the entire unit. The motor

lifting eye is for removing the motor from the unit

only.

•

CAUTION!

Do not work on or walk under the unit while it is

suspended.

Before signing the delivery receipt, inspect for damage and missing

parts. If damage or missing parts are apparent, make the

appropriate notation on the delivery receipt, then sign the receipt.

Immediately contact the carrier for an inspection.

All material must be held in the receiving location for the carrier’s

inspection.

Delivery receipts that have been signed without a notation of

damage or missing parts are considered to be delivered “clear.”

Subsequent claims are then considered to be concealed damage

claims. Settle damage claims directly with the transportation

company.

If you discover damage after receiving the unit (concealed damage),

the carrier must be notified within 15 days of receipt and an

inspection must be requested by telephone with confirmation in

writing. On concealed damage claims, the burden of establishing

that the unit was damaged in transit reverts back to the claimant.

Read the unit nameplate to verify it is the model ordered, and read

the motor nameplate to verify it is compatible with your electrical

conditions. Make sure electrical enclosures and components are

appropriate for the installation environment.

INSTALLATION

SELECTING A LOCATION _____________________________

ELECTRIC MOTOR UNITS. For most electric motor units, select a

relatively clean and dry well-lighted indoor area with plenty of space

for proper ventilation, cooling air flow and accessibility. Provide

1,000 cubic feet of fresh air per 5 horsepower. Locate the unit at

least 15 inches (38 cm) from walls, and make sure the main power

supply is clearly identified and accessible.

Unless the electrical components of the unit are specially protected

for outdoor use, do not install an electric motor unit outdoors or in

an area that will expose the electrical components to rain, snow or

sources of appreciable moisture.

WARNING FOR UNITS EQUIPPED

WITH ELECTRIC DRAIN VALVE

•

WARNING

The electric drain valve incorporates arcing or

sparking parts, such as snap switches, receptacles

and the like that tend to produce arcs or sparks

and, therefore, when located in a garage, the

compressor should be in a room or enclosure

provided for the purpose, or the electric drain

valve should be 18 inches (457 mm) or more above

the floor.

GASOLINE ENGINE UNITS. For gasoline engine units, keep the

engine at least 3 feet (1 m) away from building walls and other

equipment. Install the unit in a location with plenty of space for

proper ventilation, cooling air flow and accessibility. Do not install or

operate a gasoline engine unit in a confined area.

AMBIENT TEMPERATURE CONSIDERATIONS. Ideal operating

temperatures are between 32°F and 100°F (0°C and 37.8°C). If

temperatures consistently drop below 32°F (0°C), install the

compressor in a heated area. If this is not possible, you must

protect safety/relief valves and drain valves from freezing. If

temperatures are consistently below 40°F (4.4°C), consider

installing an external crankcase heater kit, especially if the

compressor has difficulty starting.

•

CAUTION

Never operate the compressor in temperatures

below -15°F (-26.1°C) or above 125°F (51.0°C).

HUMID AREAS. In frequently humid areas, moisture may form in

the pump and produce sludge in the lubricant, causing running parts

to wear out prematurely. Excessive moisture is especially likely to

occur if the unit is located in an unheated area that is subject to

large temperature changes.

Two signs of excessive humidity are external condensation on the

pump when it cools down and a “milky” appearance in petroleum

lubricant.

You may be able to prevent moisture from forming in the pump by

increasing ventilation, operating for longer intervals or installing an

external crankcase heater kit.

NOISE CONSIDERATIONS. Consult local officials for information

regarding acceptable noise levels in your area. To reduce excessive

noise, use vibration isolator pads or intake silencers, relocate the

unit or construct total enclosures or baffle walls.

2

http://air.irco.com