16

1-11

1-12

1-13

A

5

1

2

3

4

7

8

6

A

T1

T2

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

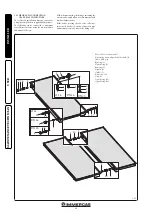

1.11 CONTROL DEVICES UNIT.

The control unit manages the solar system by

controlling the solar unit pump. The various

functions can be programmed via the 3 buttons

(Fig. 1-11) positioned under the display.

1 Forward; 2 Reverse; 3 Set (Selection / opera-

tion mode)

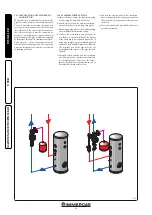

The unit (A) activates the pump when a tem-

perature difference set between the collector

probe (T1) and the boiler probe (T2) (Fig. 1-12).

The installation must only be carried out in

closed and dry environments. To guarantee

regular operation, avoid areas with strong elec-

tromagnetic fields. The regulation control unit

must be detachable from the electric network by

means of an additional device in compliance with

the Laws in force. During installation ensure that

the connection cable to the electric network and

the probe cables remain separated.

The control unit is equipped with 3 relay to which

to connect users such as pumps, valves, etc.

At the time of installation the unit is supplied

pre-set for its correct use. For personalisation

and installation information see the relative

instructions book.

Attention:

the probes supplied are used in ac-

cordance with the pre-fixed purpose:

T1 PT1000 solar probe

T2 NTC boiler probe.

Technical data:

Power Supply

220 ÷ 240 V AC

Stand-by

3,5 W

Inputs

2 temperature probes (pt

1000)

2 NTC 10 k probes

Outputs

3 relay

Room temp.

0 ÷ 40 °C

Protection type

IP 20 / DIN40050

Fuse

T 4 A

key:

A - Control

1 - Terminal T2 probe NTC

2 - Terminal T1 probe

PT1000

3 - Terminal T4 probe

PT1000

4 - Terminal T3 probe NTC

5 - terminal connection to

the mains

6 - Relay Terminals 1 -

circulation pump

7 - relay 2 terminal

8 - relay 3 terminal

key:

A - Control

key:

1 - Forward

2 - Reverse

3 - Set (Selection / operation

mode)

Содержание 3.027832

Страница 1: ...V2 HEATING SOLAR PANELS PACKS IE Instruction booklet and warning 1 041485ENG...

Страница 2: ......