6-27

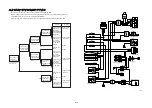

4. WHEN COOLANT OVERHEAT WARNING LAMP LIGHTS UP (engine is started)

Â

Before disconnecting the connector, always turn the starting switch OFF.

Â

Before carrying out below procedure, check all the related connectors are properly inserted.

Â

After checking, insert the disconnected connectors again immediately unless otherwise specified.

RS232 RX

CAN Lo

RS232 TX

CAN Hi

6

5

3

CN-126

31

21

24

CN-51

2

34

1

16

SERVICE TOOL

A

F

B

C

E

P DUMP

22

46

34

83

Engine ECM

CAN Hi

CAN Lo

ENGINE COOLANT

TEMPERATURE SENSOR

C

A

B

Engine harness

connector

CN-93

300L6ES04

Cause

Remedy

Check use HRDT

Disconnection in

wiring harness or

poor contact

between temp

sensor-engine

harness connector

Defective coolant

temp sensor

Check or replace

Repair or replace

(after clean)

Replace

YES

YES

NO

Starting switch : OFF

Spec : 180

̫

~160 k

̫

See table

Check resistance

between temp

sensor (A)-(B)

Check resistance

between engine

harness connector

(34)-(83)

Resistance (k

̫

)

Check Table

Temperature (˚C )

Spec : 180

̫

~160 k

̫

NO

0

30~37

25

9.3~10.7

50

3.2~3.8

80

1.0~1.3

95

0.7~0.8

Содержание HX430L

Страница 11: ...SECTION 1 GENERAL Group 1 Safety Hints 1 1 Group 2 Specifications 1 10 ...

Страница 161: ...4 6 MEMORANDUM HYUNDAI HEAVY INDUSTRIES CO LTD CONSTRUCTION EQUIPMENT DIV ...

Страница 205: ...4 50 No of pin Receptacle connector female Plug connector male 14 1 7 6 14 MG610406 KET SDL CONNECTOR 13 ...

Страница 528: ...8 88 Assemble relief valve assy 45 using torque wrench ÂTightening torque 26Ü2 6 kgfÂm 188Ü18 8 lbfÂft 31 43098TM95 ...

Страница 548: ...8 108 Remove lock nut 22 and then boot 23 14 36078RL14 2507ARL10 ...

Страница 559: ...8 119 14 15 3 Install cover 3 to body 1 and tighten bolts 14 Torque 10 12 5 kgf m 72 3 90 4 lbf ft 7 21078DA10 ...

Страница 589: ...8 149 1 STRUCTURE GROUP 11 WORK EQUIPMENT B SECTION C SECTION B SECTION A C C A B A 21078DA 44 ...