6-37

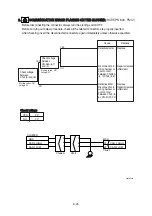

CN-21

VCC

GND

MOTOR DRIVE+

MOTOR DRIVE-

MOTOR DRIVE SIG

FEED BACK

FEED BACK

N.C

WIPER CUT SW

INT. SIG

WASHER SIG.

WASHER P/P

CONTINUE 24V

3

2

1

4

5

6

WIPER MOTOR

3

5

4

2

6

M

CN-17

CN-141

WIPER MOTOR CONTROLLER

3

2

1

4

5

6

7

8

3

2

1

4

5

6

7

8

9

10

11

12

13

WASHER PUMP

M

CN-22

WIPER CUT SW

CS-53

2

1

FUSE

NO.21

CN-5

FUSE

NO.6

18

19

15

16

17

21

20

CN-376

MEMBRANE CONTROLLER

1

2

DO-5

FUSE

NO.11

1

2

3

4

5

6

7

8

9

10

11

12

CAN_LO(2)

INT WIPER

NC

13

NC

14

OVERLOAD SW

15

16

17

18

TRVEL ALARM

19

26

27

CAN_HI(2)

GND

HEAD LIGHT

NC

GND

NC

WIPER

CABIN LIGHT

NC

WORK LIGHT

NC

NC

NC

BEACO LAMP SW

IG 24V

WASHER

34

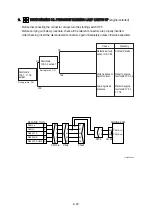

14. WHEN STARTING SWITCH IS TURNED ON, WIPER MOTOR DOES NOT OPERATE

14. WHEN STARTING SWITCH IS TURNED ON, WIPER MOTOR DOES NOT OPERATE

·

Before disconnecting the connector, always turn the starting switch OFF.

·

Before carrying out below procedure, check all the related connectors are properly inserted and the fuse

No. 6, 11 and 21 is not blown out.

·

After checking, insert the disconnected connectors again immediately unless otherwise specified.

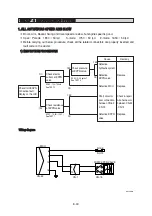

Defective wiper

cut switch

Short circuit in

wiring harness or

poor contact

between CN-141

(11)- CS-53

Defective

membrane

controller

1) Recheck fuse

No.11

2) Disconnection in

wiring harness or

poor contact

between

CN-376(1)-Fuse

Defective switch

panel

1) Recheck fuse

No.6

2) Disconnection

in wiring harness

or poor contact

between

CN-141(7)-Fuse,

CN-21(4)-Fuse

1) Recheck fuse

No.21

2) Disconnection

CN-141(6)-Fuse

ⓑ

Disconnection in

wiring harness or

poor contact

Defective wiper

motor

Defective wiper

motor controller

Replace

Repair or replace

(after clean)

Replace

Replace

Repair or replace

(after clean)

Replace

Replace

Repair or replace

(after clean)

Replace

Repair or replace

(after clean)

Repair or replace

(after clean)

Replace

Replace

Cause

Remedy

ⓐ

Check voltage

between CN-376

(1) and chassis

Check valtage

between CN-141

(11) and chassis

Check operation

wiper cut switch

Check operation

of membrane

controller LED

ON.

Check voltage

CN-141 (6) and

chassis

Check operation

of wiper motor

and controller

check voltage

CN-141 (7) and

chassis, CN-21

(4) and chassis

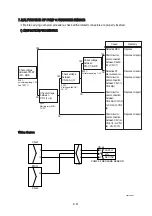

Check voltage between

CN-376 (3) and chassis

Check voltage CN-376

(11) and chassis

Check voltage CN-376

(12) and chassis

ⓐ

ⓑ

Check wiper

motor resistance

between CN-21

(2)-CN-21 (6)

Check continuity

between

CN-141 (2)-CN-376 (3),

CN-141 (9)-CN-376 (11),

CN-141 (10)-CN-376 (12),

CN-141 (5)-Chassis ,

CN-141 (1)-CN-21 (5),

CN-141 (3)-CN-21 (6),

CN-141 (4)-CN-21 (2),

CN-141 (13)-CN-21 (3)

Intermittent

Starting switch : OFF

Voltage : 20~30V

Resistance : 3~4

Ω

Starting switch : ON

Voltage : 20~30V

Washing

Sarting switch : ON

Voltage : 0~1V

YES

YES

NO

NO

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Front sliding door

open-close

Front sliding door-close

Voltage : 4~5V

Starting switch : ON

Push wiper switch button

Starting switch : ON

Vottage : 20~30V

NO

145LCR6ES15

Содержание HX145 LCR

Страница 11: ...SECTION 1 GENERAL SECTION 1 GENERAL Group 1 Safety Hints 1 1 Group 2 Specifications 1 10...

Страница 204: ...4 5 MEMORANDUM HYUNDAI HEAVY INDUSTRIES CO LTD CONSTRUCTION EQUIPMENT DIV...

Страница 553: ...8 82 Insert O rings to the relief valve 30 and reassemble them to rear cover 20 This completes assembly 17 32038SM42...

Страница 627: ...8 155 125LCR8TM30 Turn casing 1 upside down and remove oil seal 3 using jig 29...

Страница 636: ...8 164 125LCR8TM61 After assembling spring 44 in order clamp plug 41 Tightening torque 5 kgf m 36 lbf ft 31...

Страница 657: ...8 185 8 185 Remove lock nut 22 and then boot 23 14 36078RL14 2507ARL10...

Страница 668: ...8 196 14 15 3 Install cover 3 to body 1 and tighten bolts 14 Torque 10 12 5 kgf m 72 3 90 4 lbf ft 7 21078DA10...