Powermax125

Service Manual 808070

145

8 – Troubleshooting and System Tests

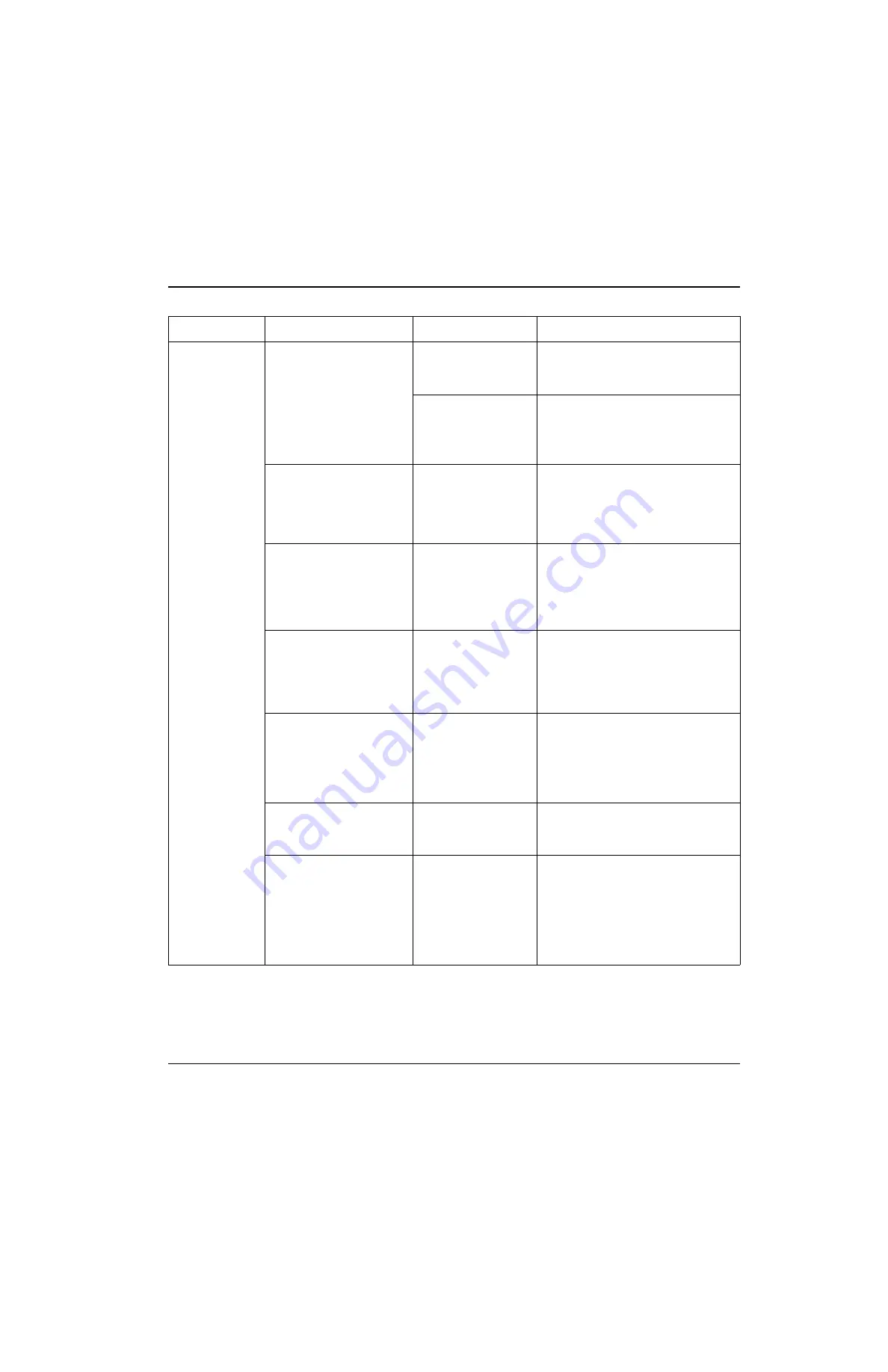

When pressing

the torch trigger

or start switch,

gas flows from the

torch, but the

torch does not fire

or fires for only a

short duration.

Worn or damaged

consumables.

• Overused or

improperly installed

consumables.

• Replace consumables.

• Oil, moisture, or

contaminants in the

gas supply line.

• Replace the gas filter element.

• Add appropriate filtration and purge

the lines with nitrogen to flush out oil

and moisture.

Damaged torch or lead

assembly.

• Electrode is not

moving properly in

the torch, or the

torch lead is

damaged.

Insufficient or excessive gas

flow.

• Gas pressure is too

high or too low, or

the gas supply is

leaking or restricted.

• Verify that the inlet pressure is 5.9 to

9.3 bar (85 to 135 psi).

• Repair air leaks or restrictions.

• Manually adjust the gas pressure on

the power supply.

Poor air quality.

• Gas filter element is

dirty.

• Oil, moisture, or

contaminants in the

gas supply line.

• Replace the gas filter element.

• Add appropriate filtration and purge

the lines with nitrogen to flush out oil

and moisture.

Insufficient input power.

Undersized electrical

supply installation.

• Breaker or fuse.

• Supply wire.

• Extension cord.

• Verify that the external electrical

power is installed according to

Faulty inverter IGBT module

or power board.

• Faulty inverter IGBT

module or power

board.

• Use an IGBT tester to check the

inverter IGBT module.

Capacitor voltage imbalance

on the power board.

• Faulty resistors on

the power board or

faulty bulk

capacitor(s).

• If the voltage across the capacitors is

not balanced, replace the power

board.

Problem

Meaning

Causes

Solution

Содержание Powermax 125

Страница 1: ...Powermax125 Plasma Arc Cutting System Service Manual 808070 Revision 1 English ...

Страница 3: ...Powermax125 Service Manual 808070 Revision 1 English April 2014 Hypertherm Inc Hanover NH 03755 USA ...

Страница 6: ......

Страница 56: ...56 Powermax125 Service Manual 808070 4 Hand Torch Setup ...