Page 71

14. Faults

14.1 Fault Management

In the event of a fault, the humidification/cool-

ing is haltet. The relevant display field is then

shown instead of the HygroMatik logo. The

display field shows a warning symbol, the

„Fault“ message and - in paranthesis - the

fault code:

When touching the fault message display

field, the unit info screen opens with the fault

message in plain text and information con-

cerning the unit and its current state.

The majority of fault messages is additionally

accompanied by the flashing of one or more

icons, allowing for a first limitation of the

cause of fault.

14.1.1 Table of fault messages, pos-

sible causes and counter-

measures

Fault (001

)

e.g.:

These icons

flash

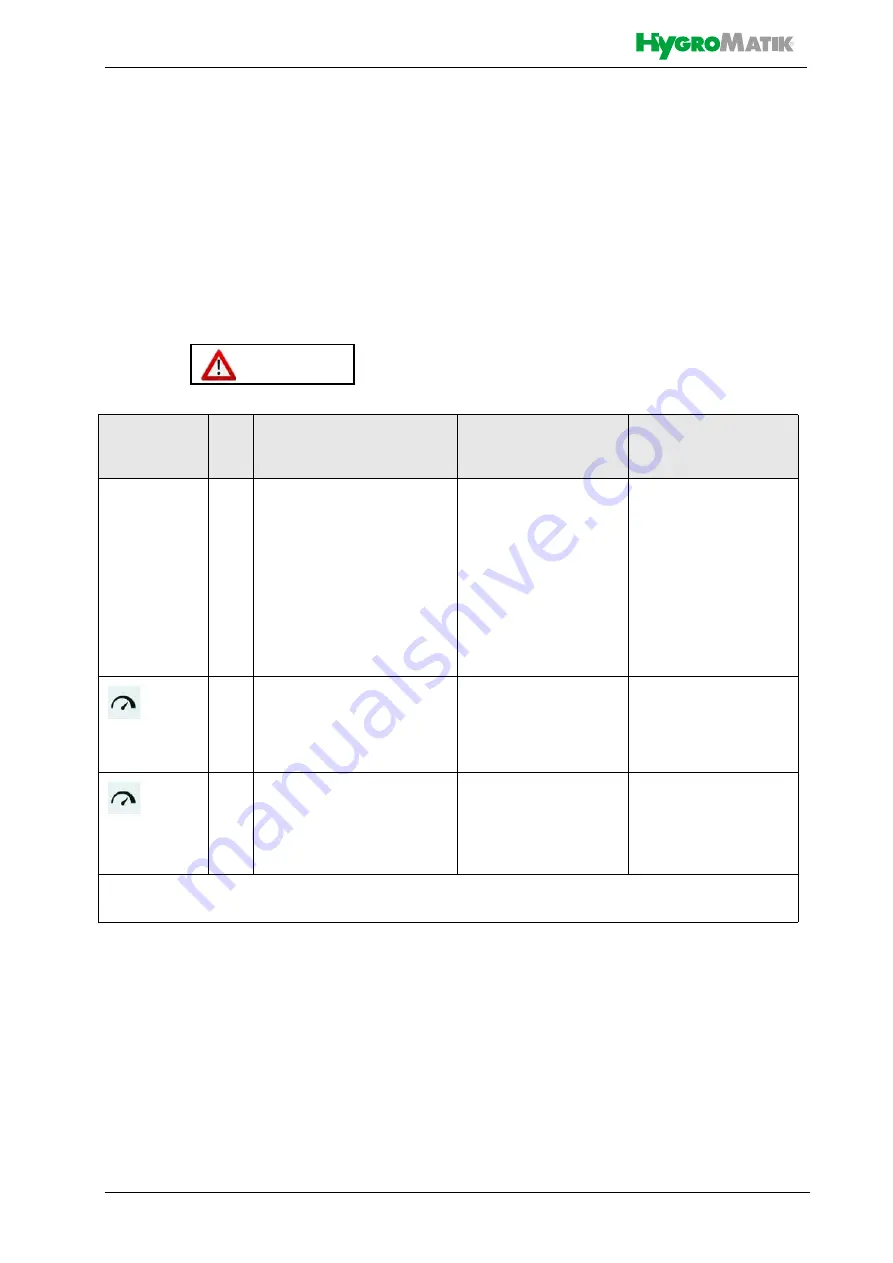

Fault

Code

Fault message

Possible cause

Counter measure

002

Expansion board

Expansion board not detec-

ted by the sofware

•

p.c.b. connection not

o.k.

•

Check firm connec-

tion of boards

•

p.c.b. not present or

defective

•

Connect board,

replace board if defec-

tive

•

CAN bus addressing

not correct

•

Check DIP switch

settings on extension

board (see fig. in sec-

tion 3.4).

022

*)

Input_current_min

The min. value of the input

signal is no plausibel

•

Sensor, wiring or

signal source defective

•

Check sensor, wiring

and signal source, if

relevant

024

025

*)

Input_resistance_OC

Input_resistance_SC

The resistance measured is

not correct („infinite“ or

„zero“, resp.)

•

Sensor, wiring or

signal source defective

•

Check sensor, wiring

and signal source, if

relevant

•

Input stage defective

•

Replace mainboard

*) When the PI controller is in use, fault codes 022 to 025 relate to the sensor. In case of an external

controller, the signal source is referred to.

Содержание HPS250

Страница 24: ...Seite 24 6 3 1 Dimensions and mounting instructions ...

Страница 85: ...Seite 85 16 Declaration of Conformity ...