MaxiCut 5-60 USER MANUAL EDITION 2-05 2012-10-23

6

3. equipment

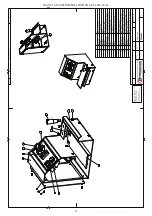

Our stationary hose cutting machine is supplied ready to use packed on a pallet.

The machine is supplied with an electric cable but without plug and main switch.

It’s the customers responsibility to install the power supply according to present

national regulations. The manufacturer recommends a lockable main switch bet

-

ween the machine and the mains. MaxiCut 5-60 OT is prepared with a smoke eva

-

cuation connection and if a smoke evacuation is connected the manufacturer re

-

commends to install a spark filter to prevent hazards.

note !

The packing material must be disposed according to current environmental

protecting regulation.

the machine is supplied initially with:

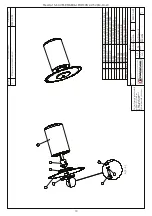

• Cutting blade HSM 400x4x50 Toothed part No: 9009-01-05

• 2 pcs of hose supports (for 3/16”-1” hose)

• Locking tool for changing cutting blade • Instruction manual

• Certificate regarding agreement according to CE-standards

3.1 Warranty

The cutting machine is guaranteed for one (1) year following the date of purchase;

the warranty is valid only if all of the instructions listed on the warranty certifi

-

cate and in this manual are fully complied with.

note !

When unpacking the cutting machine, make sure that the machine is in perfect

condition and that the package contains the parts described.

Hydroscand Mach-

ine AB does not respond for errors or missing parts not reported to Hydros-

cand Machine AB following eight (8) days after shipment.

3.2 Important

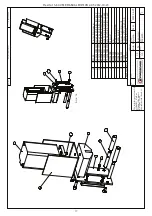

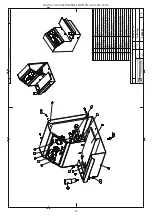

The hose cutting machine is designed, manufactured and protected for cutting 1-,

2- and 4-layers hydraulic hose with dimension from 3/16” up to 2”.

Any other use is excluded by Hydroscand Macine AB, who shall be exempt from

any liability for damage to people, property or the machine itself, caused by im

-

proper use. Do not leave the cutting machine idle running for longer periods,

without cutting anything.

Do not cut solid steel, wood or other unknown material, that can cause da-

mage to people, property or the machine itself.

Содержание MaxiCut 5-60

Страница 1: ...UseR MAnUAL edition 2 05 2012 10 23 serial number MaxiCut 5 60...

Страница 14: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 14...

Страница 15: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 15...

Страница 16: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 16...

Страница 17: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 17...

Страница 18: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 18...

Страница 19: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 19...

Страница 20: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 20...

Страница 21: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 21...

Страница 22: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 22...

Страница 23: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 23...

Страница 24: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 24...

Страница 25: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 25...

Страница 26: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 26...

Страница 27: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 27...