Filters

FIL1609-1828 / 04.19

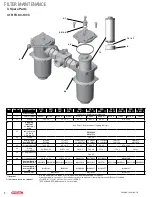

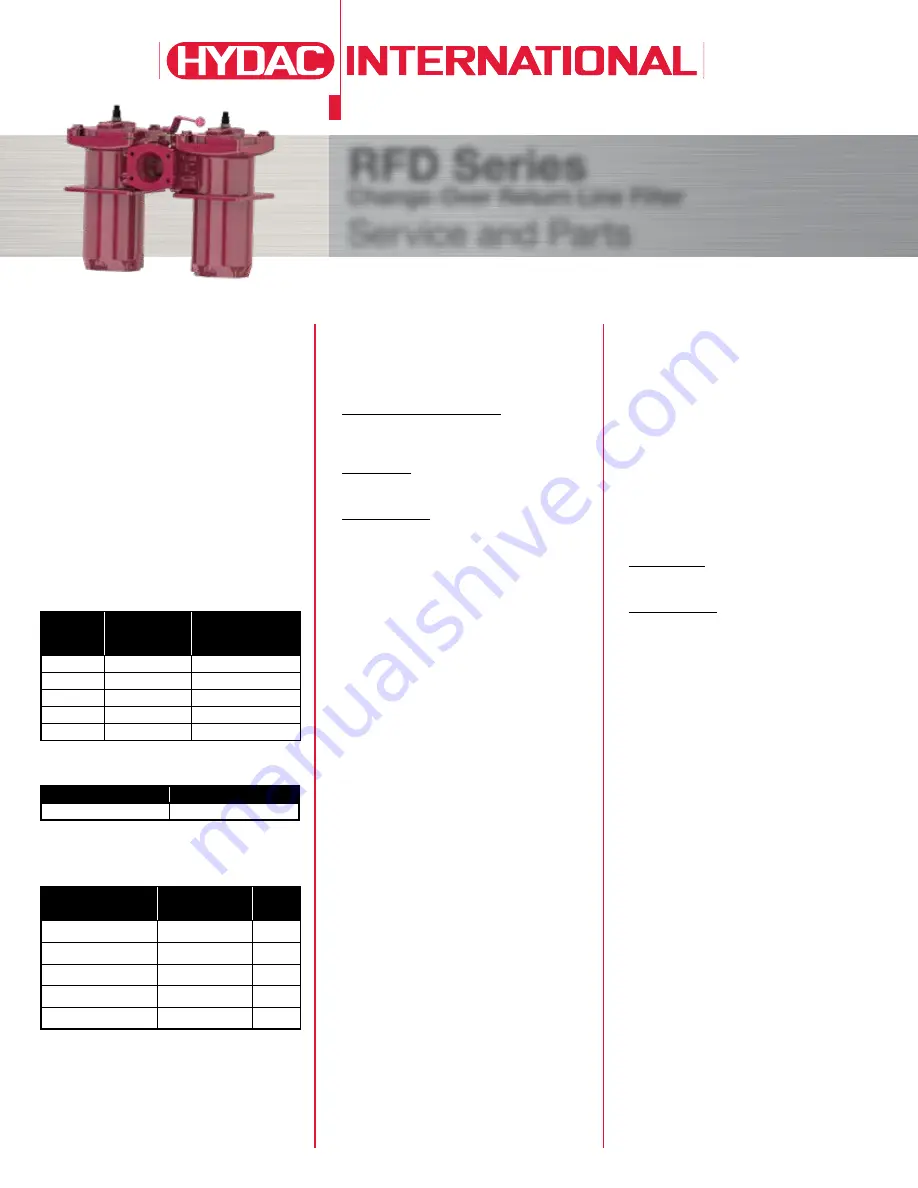

RFD Series

Change-Over Return Line Filter

Service and Parts

up to 343 gpm (1300 l/min), up to 362 psi (420 bar)

NOTE:

Contamination or incomplete pressure release

on disassembly can lead to seizing of the bowl

thread.

Filter elements which cannot be cleaned

must be disposed of in accordance with

environmental protection regulations.

1. Maintenance

1.1 General

Please follow the maintenance instructions.

1.2 Installation

Before installing the filter into the system, check

that the operating pressure of the system does

not exceed the permitted operating pressure of

the filter.

Refer to the type code label on the filter.

1.3 Commissioning

Check that the correct filter element is installed.

Install lid, screw in cover plate bolts alternately.

Switch lever to one filter side. Switch on

hydraulic system and vent filter.

1.4 Maintenance Tools

Size

Torque value

Nm [ft-lb]

Int. Lid Screws

hex bolt

Allen key

60/110

20 Nm [14]

Hex 6

160/240

20 Nm [14]

Hex 6

330

40 Nm [29]

Hex 8

660

150 Nm [110]

Hex 14

950/1300

200 Nm [147]

Hex 17

1.5 Torque Values

Type

Torque Nm[ft-lb]

VR clogging indicator 30 [22]

1.6 Torque Values for Reservoir

Mounting Bolts

Size

Torque Nm

[ft-lb]

Bolt

Size

RFD 60/110

5 [3.7]

M5

RFD 160/240

8 [6]

M6

RFD 330

20 [15]

M8

RFD 660

20 [15]

M12

RFD 950/1300

25 [19]

M16

for mechanical damage.

8. Check O-rings – and replace if necessary.

2.2 Element Installation

1. Lubricate the sealing surfaces on the filter

housing and cover plate, as well as the

O-ring, with clean operating fluid.

2. When installing a new filter element, check

that the designation corresponds to that of

the old element.

3. If present, install the contamination retainer

onto the new or cleaned filter element by

turning clockwise.

4. Place filter element carefully on to the

element nozzle in the housing.

5. Sizes 60-330:

Replace cover plate and screw in cover plate

bolts by hand; then tighten bolts alternately.

Sizes 660-1300:

Replace cover plate in correct position

(dowel pin in the housing must line up with

groove in cover plate) and turn counter-

clockwise as far as it will go. Tighten cover

plate bolts alternately.

6. Vent filter at an appropriate point in the

system.

7. Check filter for leakage.

2. Element Replacement

2.1 Element Removal

1. Switch lever slowly over to clean filter side.

Caution when installed inline:

Before opening the filter, slowly open the

vent screw and release pressure.

(release pressure in the tank, if any)

2. Size 60-330:

Loosen cover plate bolts and lift off the cover

plate.

Sizes 660-1300:

Unscrew cover plate bolts by approx. 2 turns

(no need to remove completely). Turn cover

plate clockwise until it can be lifted off by

holding near the bolts (bayonet fitting).

3. Pull out filter element(s) (with contamination

retainer, if present) by the handle. Examine

element surface for dirt residues and larger

particles since these can be an indication of

damage to components.

4. Remove contamination retainer (if present)

by turning counter-clockwise – bayonet

fitting.

5. Replace or clean filter element(s) (only W/HC

and V elements can be cleaned).

6. Clean housing, cover plate and

contamination retainer.

7. Examine filter, especially sealing surfaces,