EN 7.1

13.E2/10.17

Spare Parts List

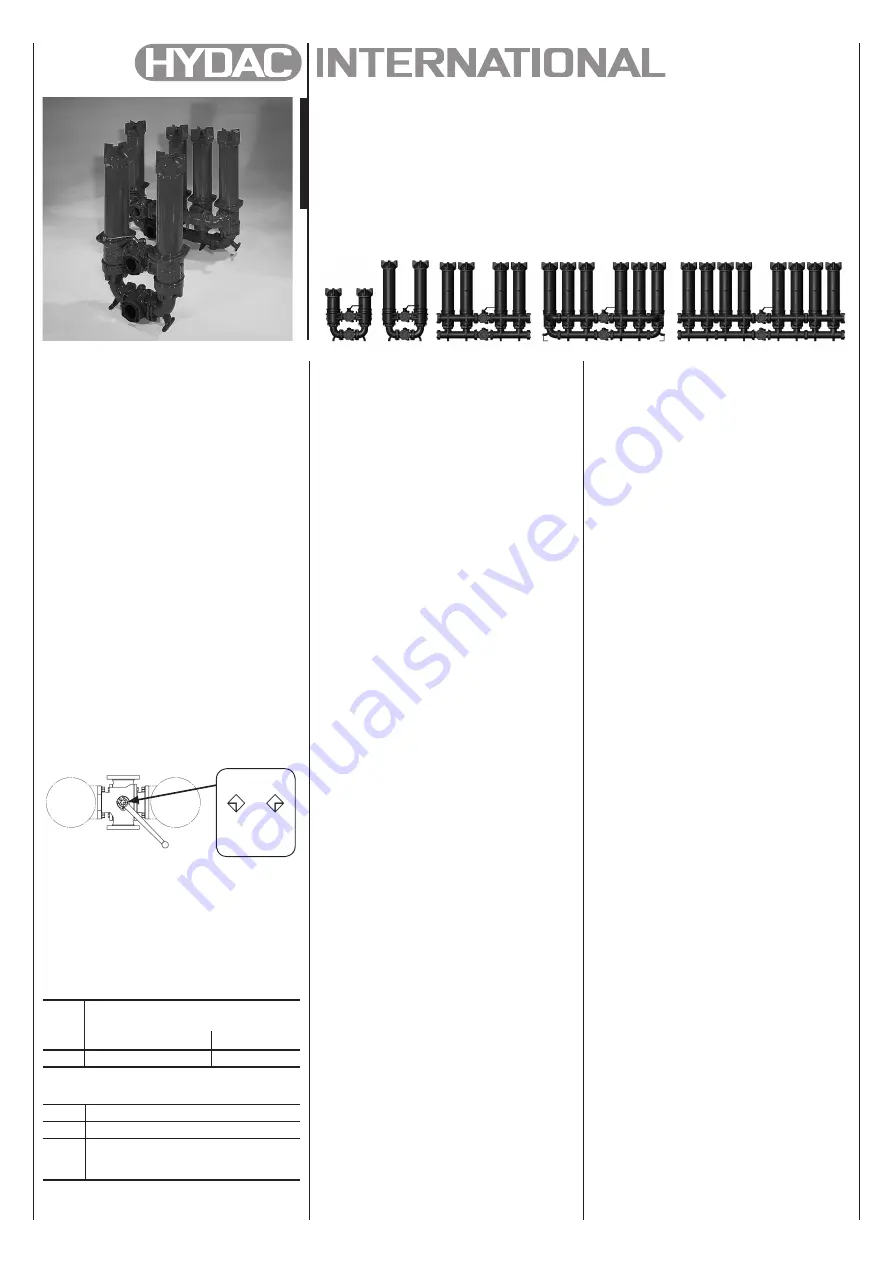

Filter NFD

Change-Over Version

up to 1600 l/min, up to 25 bar

1. MAINTENANCE

1.1 GENERAL

Please follow the maintenance

instructions!

1.2 INSTALLATION

Before fitting the filter into the system,

check that the operating pressure of the

system does not exceed the permitted

operating pressure of the filter.

Refer to the name plate on the filter!

Filters must be flexibly mounted and not

fixed rigidly to the floor or used as a pipe

support.

When installing, ensure that system

forces cannot be transferred to the filter.

A filter with a stand may only be fixed to

the ground if a compensator, expansion

loop or similar device is fitted in the line.

1.3 COMMISSIONING

Check that the correct filter element is

fitted. Screw in cover again by hand

fully and then unscrew by 1/4 turn (the

sealing effect will not be improved by

overtightening). Move the lever to the

centre position and fill filter via the

system.

Spindle setting

Left

Right

Filter in operation

Undo the air bleed screws on the

covers by a maximum of 1 rotation

and vent the filter. Close these again

as soon as oil begins exiting at the air

bleed screws. After that, change over

the lever to a filter side and check filter

for leakage.

1.4 TOOLS REQUIRED FOR

MAINTENANCE

Type Key for clogging indicator or screw

plug

VD 0 A.1

VR 0 A.0

NFD

AF width 27

AF width 19

1.5 TORQUE VALUE FOR CLOGGING

INDICATORS

Type Max. torque

VM

33 Nm

VR

33 Nm

15 Nm ( for B, BM F, LE and LZ

indicators)

2. CHANGING THE ELEMENT

2.1 REMOVING THE ELEMENT

1. Turn lever through 90° – filtration is

switched over to the other side.

2. Loosen air bleed screw(s) (if present);

remove oil drain plug(s);

Drain oil into a container (the oil must

no longer be fed to the system in an

uncleaned state!).

3. Unscrew cover.

4. Remove filter element(s) with dirt

retainer (if present) from the element

spigot. Examine element surface for

dirt residues and larger particles since

these can be an indication of damage

to components.

5. Remove dirt retainer (if present) by

turning anti-clockwise – bayonet fitting

(only on Version 1.x)

6. Replace or clean filter element(s)

(only W/HC and V elements can be

cleaned).

7. Clean housing, cover and dirt retainer

(if present).

8. Examine filter, especially sealing

surfaces, for mechanical damage.

9. Check O-rings – and replace if

necessary

2.2 FITTING THE ELEMENT

1. Lubricate the O-ring with clean

operating fluid. Apply aluminium paste

or another suitable lubricant to threads

on filter head and bowl.

2. When fitting a new filter element,

check that the designation

corresponds to that of the old element.

3. If present, fit the dirt retainer onto

the new or cleaned filter element by

turning clockwise (only for Version

1.x).

4. Place filter element(s) carefully onto

the element spigot in the housing (if

applicable, observe clip position on the

element, change over as necessary!).

5. Screw the cover on by hand fully and

then a quarter-turn back again.

6. Screw in oil drain plug(s).

7. Move the lever into centre position and

fill the filter side until oil exits from the

air bleed screw.

8. Close the air bleed screw again and

unscrew cover by one quarter-turn.

9. Change lever back to the non-changed

filter side.

10. Check the filter for leakage.

NFD

1340

NFD

2640

NFD

5240

NFD

7840

NFD

10440

NOTICE:

When replacing the pipe elbows and

connection parts, you must ensure

that the parts are assembled without

being placed under strain. If this is not

observed, the aluminium parts may be

damaged.

Filter elements which cannot be cleaned

must be disposed of in accordance with

environmental protection regulations.