CVH8, HVH8, TVH8, VA9, HVA9, TVA9: APPLICATION GUIDELINE & SERVICE MANUAL

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

38

4. Use slip couplings to install new valve with stubs back into system.

Even if stubs are long, wrap valve with a wet rag to prevent

overheating.

5. After valve is brazed in, check for leaks. Evacuate and charge

system. Operate system in both modes several times to be sure

valve functions properly.

A88342

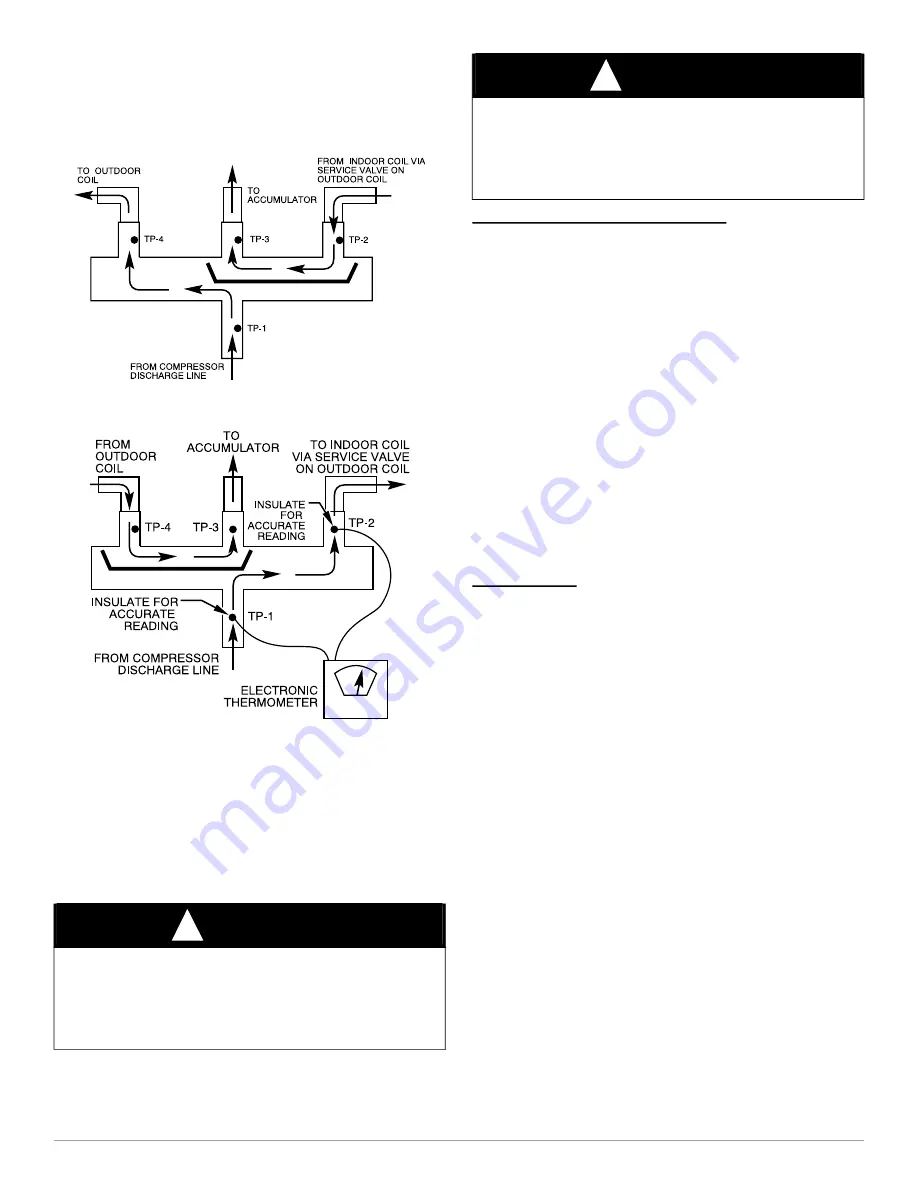

Fig. 40 – eversing Valve

(Cooling Mode or Defrost Mode, Solenoid Energized)

A88341

Fig. 41 – Reversing Valve

(Heating Mode, Solenoid De-Energized)

Liquid Line Filter Drier

Filter driers are specifically designed for R-22 or R-410A refrigerant.

Only operate with the appropriate drier using factory authorized

components.

It is recommended that the liquid line drier be installed at the indoor unit.

Placing the drier near the TXV allows additional protection to the TXV

as the liquid line drier also acts as a strainer.

Install Liquid-line Filter Drier Indoor

Install filter drier as follows:

1. Braze 5 in. liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to 5 in. long liquid tube from step 1.

4. Connect and braze liquid refrigerant tube to the filter drier.

Suction Line Filter Drier

The suction line drier is specifically designed to operate with R-410A,

use only factory authorized components. Suction line filter drier is used

in cases where acid might occur, such as burnout. Heat pump units must

have the drier installed between the compressor and accumulator only.

Remove after 10 hours of operation. Never leave suction line filter drier

in a system longer than 72 hours (actual time).

Thermostatic Expansion Valve (TXV)

All fan coils and furnace coils will have a factory installed thermostatic

expansion valve (TXV). The TXV will be a bi-flow, hard-shutoff with

an external equalizer and a balance port pin. A hard shut-off TXV does

not have a bleed port. Therefore, minimal equalization takes place after

shutdown. TXVs are specifically designed to operate with R-410A or

R-22 refrigerant, use only factory authorized TXV’s.

Do not

interchange R-410A and R-22 TXVs.

TXV Operation

The TXV is a metering device that is used in air conditioning and heat

pump systems to adjust to changing load conditions by maintaining a

preset superheat temperature at the outlet of the evaporator coil. The

volume of refrigerant metered through the valve seat is dependent upon

the following:

1. Superheat temperature is sensed by cap tube sensing bulb on

suction tube at outlet of evaporator coil. This temperature is

converted into pressure by refrigerant in the bulb pushing

downward on the diaphragm which opens the valve via the push

rods.

2. The suction pressure at the outlet of the evaporator coil is

transferred via the external equalizer tube to the underside of the

diaphragm. This is needed to account for the indoor coil pressure

drop. Residential coils typically have a high pressure drop, which

requires this valve feature.

3. The pin is spring loaded, which exerts pressure on the underside of

the diaphragm. Therefore, the bulb pressure works against the

spring pressure and evaporator suction pressure to open the valve.

If the load increases, the temperature increases at the bulb, which

increases the pressure on the top side of the diaphragm. This opens

the valve and increases the flow of refrigerant. The increased

refrigerant flow causes the leaving evaporator temperature to

decrease. This lowers the pressure on the diaphragm and closes the

pin. The refrigerant flow is effectively stabilized to the load demand

with negligible change in superheat.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

To avoid performance loss and compressor failure, installation of filter

drier in liquid line is required.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

To avoid filter drier damage while brazing, filter drier must be wrapped

in a heat-sinking material such as a wet cloth.