52

Do not operate this saw without the GUARD

SPADE LATCH (2L) engaged and the bolt [18”-

30” (450-700mm) Blade Guards] installed.

Inspect blade guards and latches frequently.

Do not use if damaged.

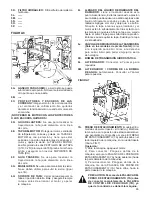

To Remove A SLIP-ON GUARD:

• Using the BLADE SHAFT WRENCH (2J) remove the rear

retaining bolt [18”-30” (450-700mm) Blade Guards].

• For 14-30” (350-700mm) Blade Guards: Use the WIRE

LANYARD (2K) to open the BLADE GUARD SPADE

LATCH (2L).

• For 36” (900mm) Blade Guards: BLADE SHAFT

WRENCH (2J) is used to pivot the BLADE GUARD

SPADE LATCH (2L) to the open position.

• Lift guard off spade.

To Install A SLIP-ON GUARD:

• Lower guard onto spade until BLADE GUARD SPADE

LATCH (2L) engages.

• Install REAR BOLT (2M) [14”-30” (350-700mm) Blade

Guards] in rear of guard using the BLADE SHAFT

WRENCH (2J).

• Verify that machine is set up correctly for the DIAMOND

BLADE (2E) diameter required for the job. Check that

the correct Engine GEARBOX PULLEY (3-1N, 3-2N),

BLADE SHAFT PULLEY (3-1L, 3-2L), BLADE FLANGE

(2B & 2F), and BLADE GUARD (2H) are installed. For

machines equipped with the three-speed ENGINE

GEARBOX (3-2A), also check that the GEARBOX

SHIFT LEVER (3-2P) is in the correct gear. See

SECTION 14, “Engine / Blade Shaft / Gearbox Speed

Adjustment”, for more details.

5

Fitting The Blade

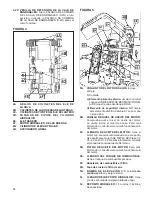

(See Figures 1 and 2)

•

Set ENGINE START SWITCH (1H) to “1” position.

• Raise Machine to a high position using the

TOGGLE SWITCH (1P) on the SPEED CONTROL

LEVER (1O).

• Set the ENGINE START SWITCH (1H) to the “0”

(OFF) position.

• Loosen Bolt on BLADE GUARD NOSE LATCH (2G).

• Raise Front Half of BLADE GUARD (2H).

• Loosen Bladeshaft Bolt (2A) Remove OUTER

FLANGE (2B).

• Fit DIAMOND BLADE (2E) to OUTER FLANGE

ARBOR (2C).

• Install OUTER FLANGE (2B) into the BLADE SHAFT

(2I) making sure that the LOCKING PIN (2D) passes

through the DIAMOND BLADE (2E) and into the INNER

FLANGE (2F).

Note the direction of rotation of the blade.

The direction of rotation is shown by an

arrow on both the DIAMOND BLADE (2E)

and the BLADE GUARD (2H). Make sure

that the contact surfaces on the DIAMOND

BLADE (2E), INNER & OUTER FLANGES

(2B & 2F) and OUTER FLANGE ARBOR (2C)

are clean.

• Rotate OUTER FLANGE (2B) and DIAMOND

BLADE (2E) in the opposite direction of blade rotation

to remove backlash.

• Install and tighten Blade Shaft Bolt (2A) while firmly

holding the DIAMOND BLADE (2E). Tighten using the

BLADE SHAFT WRENCH (2J) provided.

• Lower front half of BLADE GUARD (2H) and tighten the

Bolt on the BLADE GUARD NOSE LATCH (2G).

The Blade Shaft Bolt (2A) on the Right Hand

side has Left Hand threads. The Blade Shaft

Bolt (2A) on the Left Hand side has Right

Hand threads.

Slip-On blade guards are provided with a

safety BLADE GUARD SPADE LATCH (2L)

which engages the support spade and a

REAR BOLT (2M) [18”-30” (450-700mm) Blade

Guards], to retain the rear of the guard.

6

Starting The Saw

(See Figures 1, 2 and 5)

Always pay extreme care and attention to the

preparation of the machine before starting.

Remove all wrenches and tools from the floor

and the machine.

Always keep blade guard, belt guards and

fan guards in place.

• Follow all operating instructions and warnings in this

manual and on the machine.

• Close the WATER VALVE (1T).

• Mark the surface to be cut by drawing a line where the

cut is to be made.

• Pull out Handle Bars (1B) to desired length and tighten

Knobs (1A).

• Lower the Front Guide (6D) and align the Front Guide

(6D), Rear Guide (6F) and DIAMOND BLADE (2E) with

the line on the surface.

• To start the saw when no water pressure is present, set

the WATER SAFETY SWITCH (1L) to “0” (OFF).

• Set SPEED CONTROL LEVER (1O) to the STOP

POSITION (1BB). Saw will not start unless the SPEED

CONTROL LEVER (1O) is in the STOP POSITION

(1BB). Check to be certain the TRANSMISSION

BYPASS VALVE (6J, Front Pivot Models Only) is closed

in the down position.

• Set the BLADE CLUTCH SWITCH (1V) (if equipped)

to “0” (OFF).

Содержание FS 4800 D

Страница 7: ... NOTES NOTAS REMARQUE ...

Страница 31: ...31 NOTES NOTAS REMARQUE ...

Страница 37: ...37 FS 4800 D DIESEL SPECIFICATIONS Standard CE Models ...

Страница 39: ...39 ESPECIFICACIONES DE DIESEL FS 4800 D Modelos estándar y CE ...

Страница 41: ...41 SPÉCIFICATIONS DU FS 4800 D DIESEL Modèles standards et CE ...

Страница 112: ...542 20 10 97 2006 44 ...