1.11.2 Checking the Appearance of Metal Contact Strips

This topic describes how to check the metal contact strips and how to check whether an

assembled RJ45 connector is qualified.

Context

l

To ensure proper contact between the crimped parts and the core wires, the heights and

sizes of the metal contact strips must be uniform and standard.

l

The metal contact strips must be parallel to each other, with an offset less than 5°. The

top margin of a strip must be parallel to the axis of the connector, with an offset less than

10°.

l

To ensure expedite conduction, the surface of the metal contact strips must be clean.

l

The metal contact strips must be in good contact with the RJ45 socket. The plastic septa

must remain intact and must be aligned properly.

l

The soldering edge of a metal contact strip must surpass the ends of the core wires. The

ends of the core wires must be in contact with the edge of the RJ45 trough. In principle,

the distance between them must be less than 0.5 mm (0.02 in.).

Procedure

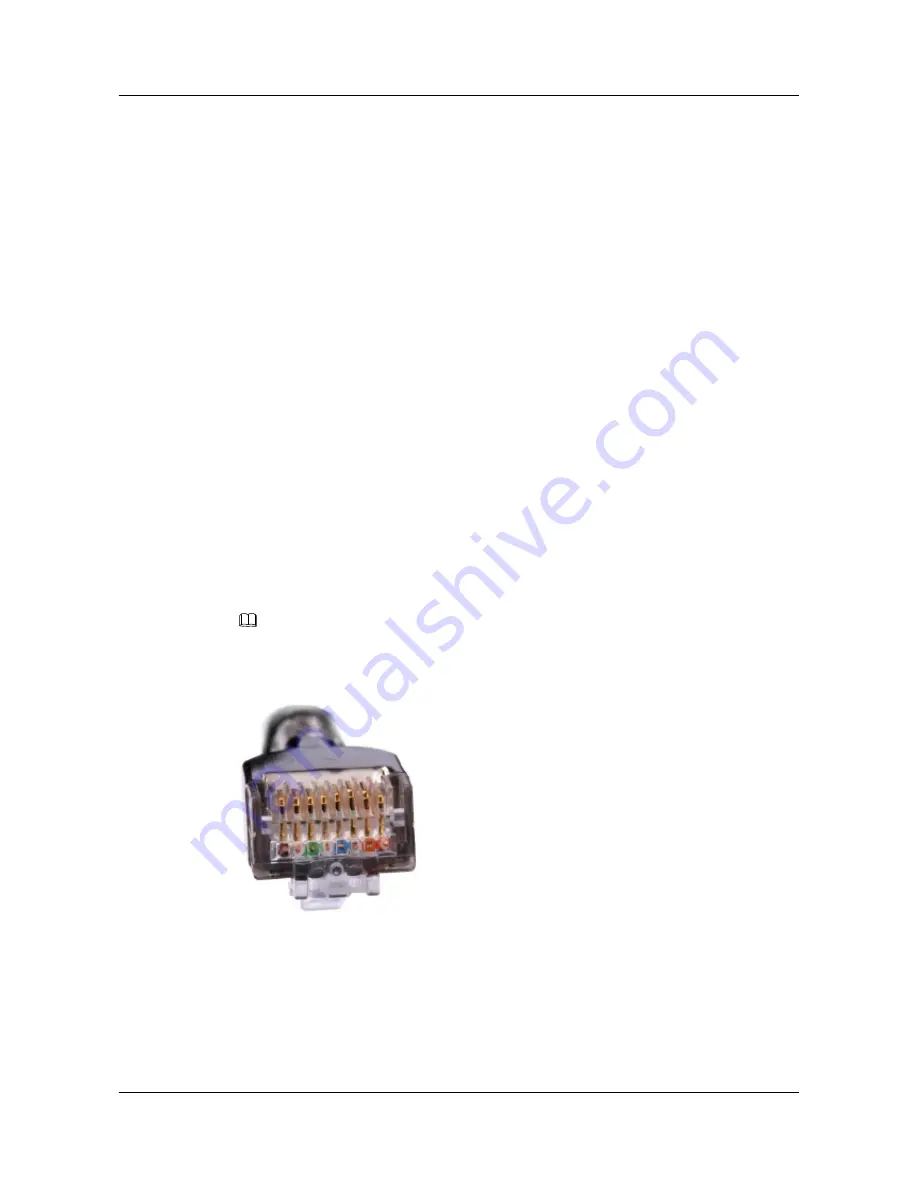

Step 1

Hold the crimped connector, with the front side facing you, and check whether the metal

contact strips are of the same height. In principle, the height is 6.02 mm (0.237 in.) ± 0.13 mm

(0.005 in.). If a measuring tool is not available, you can compare the connector with a

standard connector.

Figure 1-46

shows an unqualified piece, and

Figure 1-47

shows a

qualified piece.

NOTE

All unqualified pieces must be crimped again.

Figure 1-46

Metal contact strips of different heights

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Issue Draft A (2016-03-30)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

47