9

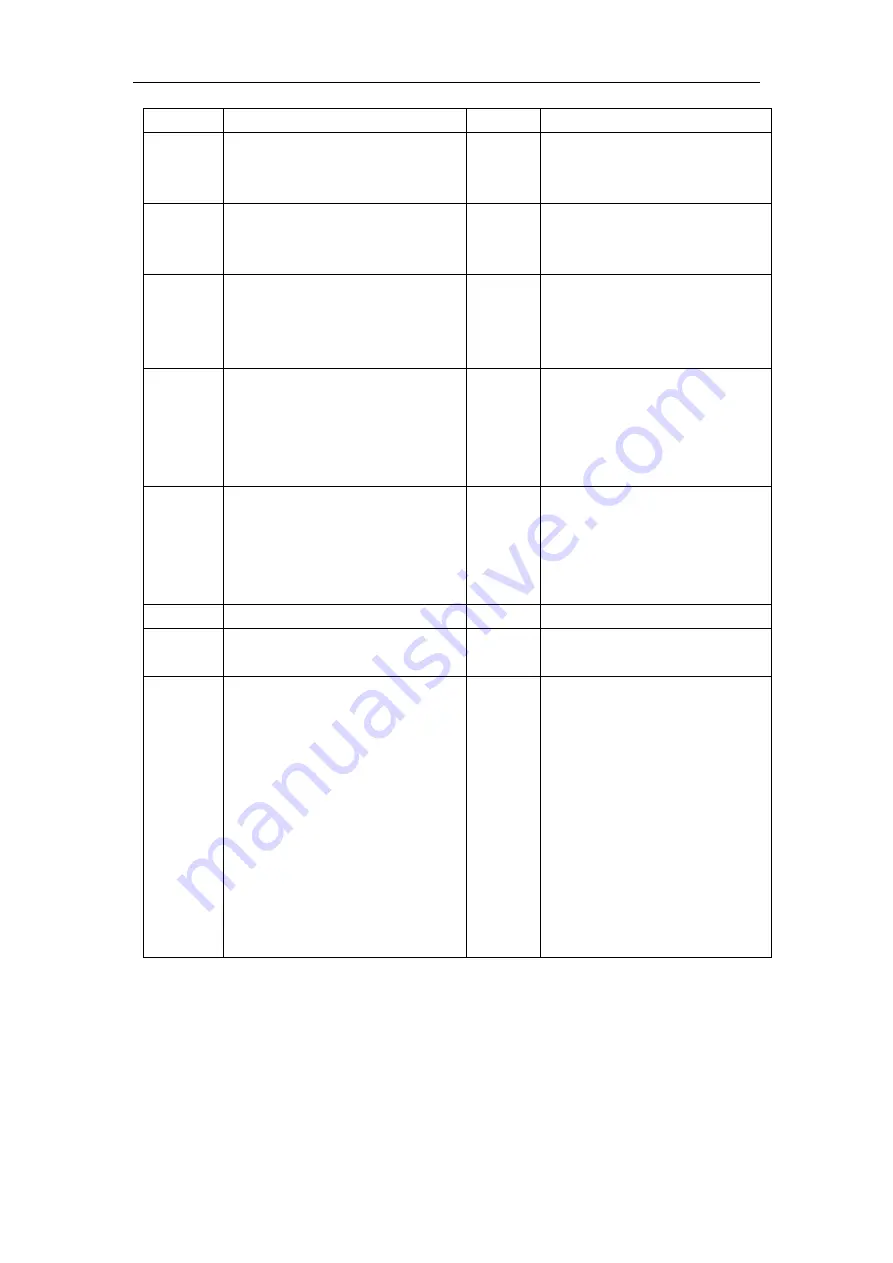

Light

Condition

Display

Status/Possible Cause

E01

Over-Current- Check output

diodes, main transformer and

IGBT on the invert board.

Temp

On

E02

Over-Temperature- Stop

cutting, allow machine to

cool down.

E03

No system is established-

Check output diodes, main

transformer and IGBT on the

invert board.

Nozzle

Repetative flashing rate of 3

quick circles, then a 1 second

pause for a 15 second period or

until torch trigger is pressed

again, whichever comes first.

E04

No pilot arc established

possibly due to a loss of

current- Check consumables.

Nozzle

Repetative flashing rate of 3

quick circles, then a 1 second

pause for a 15 second period or

until torch trigger is pressed

again, whichever comes first.

E05

Consumables in torch failed

to separate during pilot arc

possibly due to being stuck-

Check consumables.

E09

No input power.

Cup &

Nozzle

Repetative flashing rate of one

quick circle.

E11

Torch cup is loose or off.

Pressure Repetative flashing rate of 1

quick circle.

E13

E13 means air pressure is out

of range. H means air

pressure has exceeded setting

range. L means air pressure is

under setting range.In

Normal/Grid,the setting

range of air pressure is 4.2-

5.6bar. In Gouging,the

setting range of air pressure

is 2.1-3.5bar. In Marking,the

setting range of air pressure

is 2.1-3.1bar.

Содержание MicroCut 45 DV

Страница 2: ...I...

Страница 13: ...8 3 Two different kinds of cutting torches Figure 8 Hand Torch Figure 9 Machine Torch 4 Alarm display...

Страница 19: ...14 6 Cutting Guidelines...

Страница 20: ...15 7 Consumable Breakdowns Consumable Parts Breakdown Hand Torch Consumable Parts Breakdown Machine Torch...