-

20

-

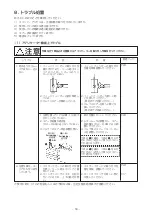

Trouble

1. The terminal is not

fed smoothly. The

terminal is not fed.

Cause

Corrective measure

Caution :

To carry out troubleshooting, be sure to detach the applicator from the crimping machine in prior.

8. Troubleshooting

Before starting troubleshooting, the following has to be checked.

* Contact our Production Engineering Department for consultation for use or any unclear points.

2. Carrier deforms to

take S-shape during

clamping.

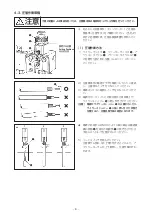

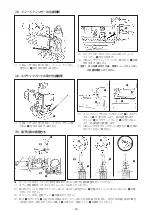

1. The feed finger is mounted out of position and

is not aligned with the center of the pilot hole.

2. Top of the feed finger has worn out.

3. Cam follower has worn out.

1. Terminal is not placed on the crimping

position (just above the anvil).

2. Compressed air pressure is not regulated

to the proper value (0.4 to 0.6 MPa).

3. Compressed air supply to the valve is not

properly regulated.

1. Re-adjsut the mounting position of the

feed finger.

2. Replace the feed finger with a new one.

(Consult us for service.)

3. Replace the cam follower with a new

one.(Consult us for service.)

1. Place the terminal at the correct

crimping position.

2. Adjust the regulator so that an

adequate quantity of compressed air is

supplied (0.4 to 0.6 MPa).

3. Properly adjust the speed control

mounted on the valve.

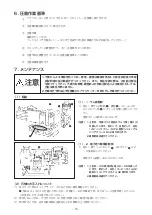

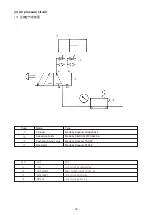

Loosen knob

1

and turn knob

2

in

direction

A

to increase the “feeding”

and “returning” speeds.

Loosen knob

1

and turn knob

2

in

direction

B

to decrease the “feeding”

and “returning” speeds.

1. Re-adjust the attaching position of the

scrap guard.

2. Replace the cut-off punch with a new

one.

Related page

故障

1. 端子不能顺畅

传送。

原因

处理

1. 供料指的安装位置偏移,没有对准卷盘端子

传送的操作杆孔的中心。

2. 供料指的前端磨损。

3. 凸轮磨损。

1. 端子没有安放在压接位置 ( 砧台的正上方 )

2. 空气供给压力不是规定值 [0.4 〜 0.6MPa]。

3. 阀门的空气供给调整不正确。

1. 废屑防护器的安装位置不正确,与卷盘端子

传送器相碰。

2. 切断钳上有伤痕,上下动作不灵活。

1. 重新调整供料指的安装位置。

2. 请更换新的供料指。(请与本公司联系。)

3. 请更换新的切断钳。(请与本公司联系。)

1. 请安放到端子位置。

2. 请调整调节器、调整空气供给量为 [0.4

〜 0.6MPa]。

3. 请调整阀门的速度控制。

拧松

1

,向

A

方向转动旋钮

2

之后,

「送气用」、「返回用」的速度变快。

拧松

1

,向

B

方向转动旋钮

2

之后,

「送气用」、「返回用」的速度变慢。

1. 重新调整废屑防护器的安装位置。

2. 请更换新的切断钳。

2. 压 接 作 业 中,

传送器变形成

S 形。

参照页

P24

P24

P24

P18

* 有关使用方法,如有不明之处,请与本公司生产技术部联系。

注意

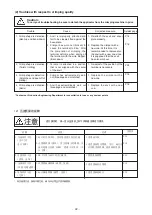

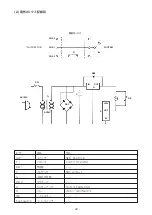

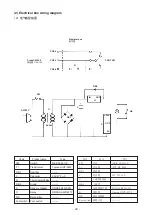

(1) Troubles with respect to functions of the applicator

4) Is the air supply connected to the crimping machine?

5) Is the power to the crimping machine turned on?

1) Are the correct crimpers and anvils attached?

2) Is the applicable terminal used?

3) Is the electric cable that falls within the applicable range used?

8. 故障处理

请首先确认以下事项。

1) 夹紧器、砧台是否安装正规的零件。

2) 使用的端子是否是适合端子。

3) 使用的电线是否是适合范围内的电线。

(1) 供料器功能的故障

4) 是否连接了空气源。

5) 是否接通了电源。

1. Scrap guard is attached to a wrong position and

comes in contact with the reel terminal carrier.

2. Cut-off punch has scratches and marks,

impairing smooth up- and-down movement

of the terminal.

进行操作时、请一定从压接机上卸下供料器后再进行操作。

P24

P24

P24

P18

Содержание CM-105

Страница 2: ......

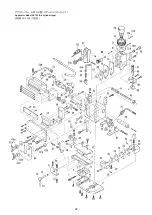

Страница 45: ... 28 アプリケーター AP105 型 エアーシリンダータイプ Applicator Model AP105 Air cylinder type 供料器 AP105 型 气缸型 ...

Страница 50: ... 33 MEMO ...